Actions after Rana Plaza tragedy: Time to build on the progress

When the Rana Plaza building came crashing down on April 24, 2013, Bangladesh's garment sector received a massive jolt and apprehension kicked in that the sector's growth might slow down.

The fear deepened further two months later when the US, citing poor labour rights and working conditions, scrapped the Generalised System of Preferences (GSP), which allowed exporters, except apparel makers, to ship goods to the American market, the single largest export destination for the country, without any duty.

But Bangladesh managed to survive as all stakeholders, including the government and the international community and retailers and brands acted promptly to fix the problems and ensure workplace safety and improve labour rights in the following years.

The government amended the labour law twice and formulated the guideline for applying the labour law. The industry responded positively.

In the last nine years, the grave tragedy has turned into a trigger for the betterment of the garment industry in particular and the entire manufacturing sector in general.

Today, Bangladesh is home to some of the top green apparel factories in the world. Labour laws have been amended. Workers' rights have improved and unions are being allowed. As a result, the shipment to America and other markets, particularly garments, which account for about 85 per cent of national shipment, has remained resilient.

Bangladesh raked in $38.75 billion in export earnings in the last fiscal year, up from $30.18 billion in 2013-14.

Apparel shipment grew from $24.49 billion to $31.46 billion during the period.

Between July-March of the current fiscal, $31.42 billion worth of garments was shipped, registering 33.81 per cent year-on-year growth.

What is more, the efforts to improve working conditions have not been limited to the garment sector alone.

The government has made it mandatory to ensure adequate safety measures at all factories.

Khondaker Golam Moazzem, research director of the Centre for Policy Dialogue, says the collapse shook the garment industry.

"The lesson was long overdue although nobody had expected it. But the most unfortunate thing for us is that we don't take any lesson if we don't face any major incident."

He says the sector has learnt its lesson albeit at the expense of many lives, has taken measures and regained its lost glory. As a result, orders are flowing in huge numbers.

Today marks the ninth anniversary of the building collapse, which killed 1,138 workers and left 2,500 workers injured, mostly women workers, who were forced to enter their workplaces in absence of trade unions despite discovering large structural cracks in the building just a day earlier.

"We don't want any more Rana Plaza collapse," said Faruque Hassan, president of the Bangladesh Garment Manufacturers and Exporters Association.

"We have improved workplace safety with the recommendations from the Accord and the Alliance. As a result, our image has been restored and buyers' confidence in us has returned,"

Hassan says garment factories have invested in machine and innovation, improved workplace safety and enhanced workers' rights over the last nine years.

So, the garment export has been not affected. Rather, Bangladesh has turned into one of the best global garment souring countries in the world.

In line with the recommendations from two international platforms, the Accord on Fire and Building Safety in Bangladesh and the Alliance for Bangladesh Worker Safety, Bangladesh has invested more than $3 billion to improve workplace safety.

Now, Bangladesh is the global champion in green garment factories having 157 Leadership in Energy and Environmental Design (LEED) certified garment factories.

More than 500 garment factories are waiting to be certified by the United States Green Building Council. All of these efforts have helped brighten the image of the sector and boosted the country's exports.

Bangladesh is performing strongly in the US despite one of the highest tariff rates of 15.62 per cent, thanks to competitive prices and higher demand.

For instance, AK Azad, one of the leading garment entrepreneurs, shipped $580 million worth of apparel items in 2021. Of the shipment, 95 per cent were supplied to major American retailers and brands such as GAP, VF Asia, Kontoor and Kohl's.

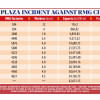

In 2013-14, Bangladesh exported goods worth more than $5.58 billion to the US, of which 95 per cent were garments. It was $6.13 billion in FY19 and $5.94 billion in FY21.

Between July and March, garment export to the US grew 53 per cent year-on-year to $6.58 billion. The shipment is expected to accelerate as orders are shifting from China and thanks to massive capacity building by local exporters.

"We expect the garment export to the US to grow even higher at the end of this fiscal year as we are overbooked with orders. Buyers' confidence in Bangladesh has received a boost from our efforts aimed at improving workplace safety," Hassan said.

M A Razzaque, research director of the Policy Research Institute of Bangladesh, said in the US markets, all the exporters have to face equal duty, as the American government does not allow preferential trade facilities on garment shipment.

CPD's Moazzem, however, points out that it seems that the reform initiative has slowed down and there is complacency.

"But this complacency could be costly. By taking measures after the Rana Plaza building collapse, we have just laid down the foundation. But we have lost the momentum."

He says the country's ongoing efforts are marked by a lack of coordination, transparency, accountability, weaknesses, and lack of skills.

"As a result, we see fire incidents every now and then. If this continues, we can't rule out the possibility of any major tragedy."

For all latest news, follow The Daily Star's Google News channel.

For all latest news, follow The Daily Star's Google News channel.

Comments