Climate-induced disruptions could cost Bangladesh $700b in apparel exports by 2050

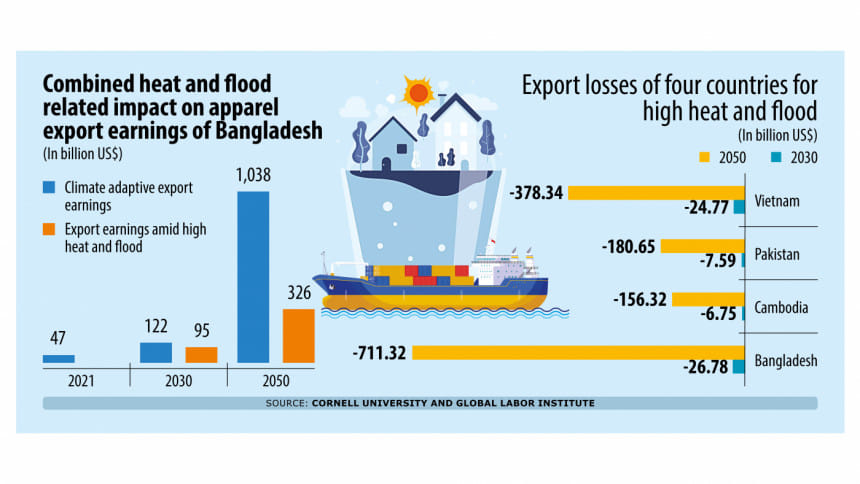

Bangladesh could lose a staggering $27 billion in annual apparel exports by 2030 if it does not adopt a climate-adaptive approach due to high heat and floods, according to a new study.

About 2.5 lakh employees in the sector will lose their jobs due to such climate-induced disruptions by the year.

The study -- Climate Resilience and Fashion's Costs of Adaptation -- was jointly conducted by Cornell University and Schroders.

The findings were jointly unveiled by Mapped in Bangladesh (MiB) and Cornell University's Global Labor Institute (GLI) under the School of Industrial and Labor Relations at the Lakeshore Hotel in Dhaka yesterday.

Jason Judd, executive director at GLI, presented the study findings.

Focusing on production hubs in Bangladesh, Cambodia, Pakistan, and Vietnam, the research reveals that these regions could lose more than $65 billion in export earnings and see the loss of nearly 1 million jobs by 2030 due to climate-induced disruptions.

"In the longer term, the impact will be excruciating for Bangladesh," the study said, adding that the nation may lose $711 billion, or 68.5 percent of its total foreign currency earnings from apparel exports by 2050.

It recommended immediate actions to address the challenges.

The researchers also analysed the climate vulnerability of 32 apparel production hubs, including Dhaka and Chattogram and showed that exposure to heat and flooding was widespread.

They mapped the supply chain footprint of six global apparel brands across the four production centres.

The findings showed that workers and manufacturers of all six brands faced productivity impacts from extreme heat and flooding, conservatively estimated to be equivalent to 5 percent or more of their net operating profits after tax.

It added that fashion brands and retailers tempted to shift sourcing away from climate-vulnerable centres would struggle to build the large-scale capacity they benefit from in South and Southeast Asia.

Several manufacturing hubs stand out in 2030 and beyond for their vulnerability to high heat and humidity and flooding: Colombo, Dhaka, Chattogram, Yangon, Delhi, Bangkok, Phnom Penh, and the Dongguan-Guangdong-Shenzhen region in China.

Workers in Dhaka reported missing three days of work per month due to heat- and flood-related illness in the summer months from May to July, costing them Tk 1,200 to 1,500 per month.

The study recommended treating heat and flood events as health hazards, with paid leave for events and related illnesses. It also called for providing the rights to stop work under such conditions.

Jason Judd emphasised the need for investors to engage with apparel companies and stakeholders and highlighted the gap in risk management strategies, which often overlook adaptation measures.

He called for the establishment of social protection mechanisms and the commitment of climate adaptation finance to safeguard workers against the effects of climate change.

The study stressed the need for a collective response, including global and national bargaining, to address the challenges faced by the apparel sector.

Binding agreements should be established and formal partnerships must be fostered between brands, manufacturers, unions, and governments to address and adapt to climate breakdown.

The study suggested brands and suppliers explore the return on investment from adaptation measures and support suppliers to retrofit or relocate to lower-risk locations.

It was also recommended the government integrate climate adaptation and worker rights-related factors into trade policies.

MiB and its implementing partner BRAC University's Centre for Entrepreneurship Development were part of the study and provided necessary data support to Cornell University.

Afshana Choudhury, lead operations officer at MiB, emphasised the policy implications of the study in navigating the challenges and opportunities presented by climate change in the fashion industry.

"Buyers should increase prices so that factories can adopt eco-friendly initiatives. At the same time, factory owners should not contaminate rivers and pollute the environment."

She advised apparel factory owners to set up green factories and refrain from cutting trees.

For all latest news, follow The Daily Star's Google News channel.

For all latest news, follow The Daily Star's Google News channel.

Comments