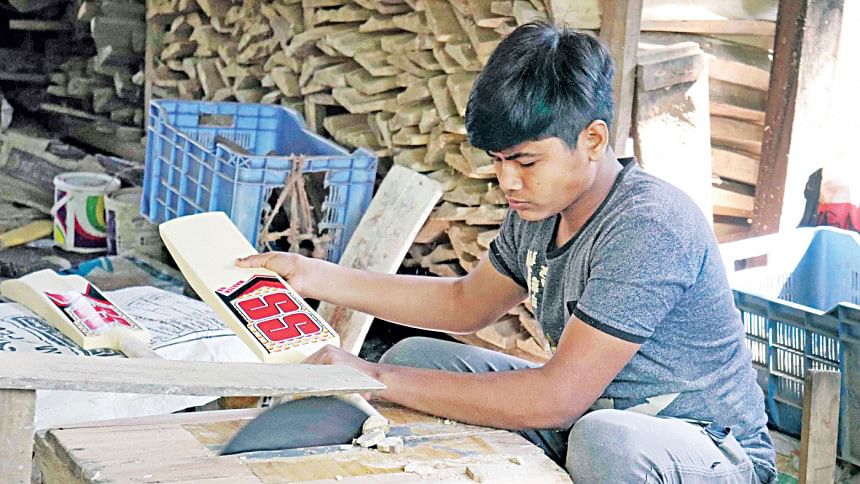

Cricket bat making hub battles to stay afloat

The cricket bat making hub that has boomed in the last three decades in Pirojpur's Nesarabad upazila might soon go out of business as producers have been facing severe losses since the pandemic hit the country two years ago.

About 200 factories in five villages -- Uribuniya, Binna, Khejurbari, Jilbari and Katakhali -- under Baladia union in the upazila have emerged as the country's cricket bat manufacturing hub thanks to ample supply of timber, lower labour cost, and requirement of low investment.

Collectively, they would churn out 20 lakh bats alone during the main season running from October to March. Their clients included sports accessories wholesalers and retailers across Bangladesh as well as corporate offices.

But sales have plummeted since the pandemic arrived as the government enforced countrywide lockdowns, which forced bat makers to keep their factories shut for several months.

Although the closure of educational institutions for most of the part throughout the crisis has offered plenty of time to children and youth alike to play cricket, a majority are keen to spend more time online or in front of televisions as they stay indoors.

As a result, the bat-makers are in trouble. Now, the number of factories has come down to a maximum of 50.

"Fairs are the main marketplace for our products but they have remained suspended for the last two years. We also don't see any hope this year," said Maksudur Rahman, a producer in Jilbari.

Besides, the number of workers has decreased alarmingly at existing factories, he added. Only two workers work at his factory instead of seven before the pandemic.

About 2,000 people were, directly and indirectly, involved with bat manufacturing in the five villages.

"If we can't sell our products, what is the point of producing them?" said Md Kamrul Hasan, another bat-maker in Jilbari.

Many people who were involved in this trade have changed professions in the last two years as the pandemic caused demand to plummet, making it difficult for them to rely on inadequate sales of the accessory to make a living.

The production cost of making bats has also increased but the price of finished products remains the same.

"Production has decreased alarmingly in line with falling demand and if this continues, the industry will fully vanish from the upazila within a few years," said Atikul Islam Rony, another bat maker.

He says that although schools, colleges and universities have remained closed for most of the time throughout the pandemic, students are not interested in playing cricket.

"Now the scenery of youngsters playing cricket in the playground is rare in many areas."

During a recent visit to Jilbari, only 10 to 12 factories were found to be operational against at least 70 before the pandemic.

Only two workers were making bats in two of these factories.

Some bats are still being sold as the coronavirus situation has improved. Still, manufacturers say they will be able to sell 2 lakh bats at best.

"The sales have dropped by half," said Firoz Khan, owner of New Inter Sports, a sports accessories retailer in the district town.

Abdur Rahim, a factory owner, used to sell bats worth Tk 20 lakh to Tk 30 lakh during the peak season before the crisis. "Now, we are passing a difficult time," he said.

Factory owners say they have not got any compensation from the government during the pandemic.

"But what would we even do with the loans if we can't use them to produce bats for sale?" a factory owner said.

"It has become very difficult for us to survive," he added.

For all latest news, follow The Daily Star's Google News channel.

For all latest news, follow The Daily Star's Google News channel.

Comments