Sugarcane shortage a concern for Carew

Carew & Co (Bangladesh) Ltd, the country's sole state-owned distillery, could face a shortage of sugar as sugarcane threshing at its mill in Chuadanga hit an all-time low this season.

This is the first time in Carew's 84-year history that it may have to make do with an inadequate supply of sugar, which is a key ingredient for preparing alcohol.

Company sources say they cultivated sugarcane on just 4,627 acres of land in the district this season, down by about 46 per cent compared to 8,532 acres during the same period in financial year 2020-21.

Of the total acreage, Carew grew the crop on 989 acres of land across 10 agricultural and experimental farms while people in the mill zone planted the rest.

The sugar mill incurred losses of Tk 69.5 during the FY2020-21 threshing season but now, company officials fear this year's losses may even exceed Tk 72 crore.

The primary cause for such a disruption to the supply chain has been identified as a lack of fertilisers while many farmers are also to blame for supplying an older variety of the crop instead of the new, higher-yielding one.

And since the stalk takes about one-and-a-half years to grow, farmers are switching to more lucrative crops, such as paddy, jute and corn.

Sugarcane farmers in the mill's zone said no loans were given to pay for fertilisers, pesticides and irrigation, which require 11 per cent interest to be paid when collecting them.

In addition, the mill hands out permits for the purchase of sugarcane from local farmers, but in many cases the farmers do not get a permit before their crops rot in the field.

Carew officials claim that the recent closure of six sugar mills created a negative perception among farmers about planting sugarcane.

Besides, farmers claim that they are losing interest in sugarcane cultivation due to the mismanagement of sugar mills.

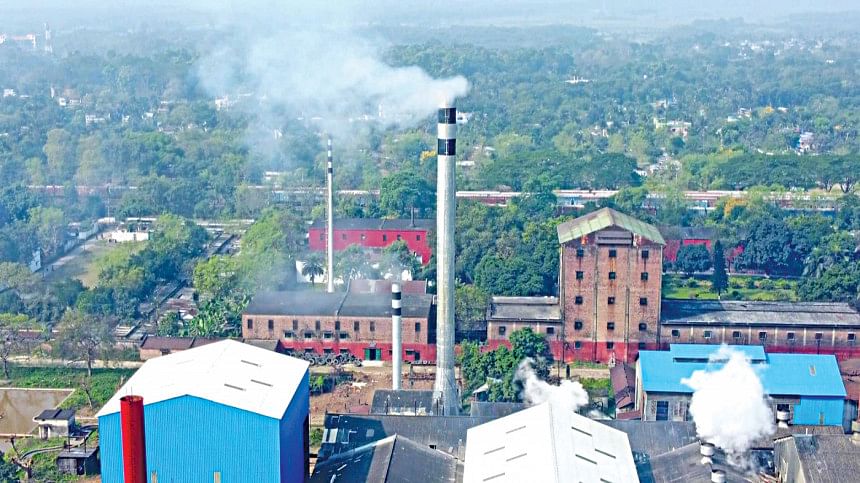

Carew's large industrial factory was first established in 1938 with a combination of a sugar industry, distillery and commercial farms in Chuadanga.

The institution was nationalised post-independence in 1973 and since then, it has been operating as Carew & Co under the Bangladesh Sugar and Food Industries Corporation. A total of 1,200 people are directly involved with the business while about 15,000 others are indirectly employed.

At the same time, various organisations have been established in the area centring this agro-based sugar industry. There are 3,335.56 acres of land in the mill's farming zone, of which commercial farming is conducted on 3,055.84 acres.

Each season, the sugar mill authorities plant sugarcane on an average of about 1,500 acres of land.

According to Carew sources, it was possible to keep the mill running for only 51 days in the current season, which ended on February 13, to produce 3,023 tonnes of sugar. The average rate of sugar extraction was 5.62 per cent.

However, the mill authorities have yet to reveal how much money has been lost this season due to the supply disruption.

The mill produced 5,883 tonnes of sugar in 2020-21 with an average extraction rate of 5.25 per cent but still counted losses of about Tk 69.51 crore that season.

In the 2019-20 season, the mill produced 5,142 tonnes of sugar and incurred losses of around Tk 70.77 crore.

Abdul Bari, general secretary of the Sugarcane Welfare Association, said the mill is yet to be modernised as it still relies on manual labour to collect and thresh sugarcane.

"This ancient method takes more time and manpower while production is low," he said.

"As a result, the production cost of sugar is constantly increasing every year," Bari added.

On the other hand, Mosharraf Hossain, managing director of Carew, said modernisation of the mill has begun.

"Work is underway to implement some new plans to cover the losses of different units," he said, adding that even if there is no profit next season, steps are being taken to ensure that losses are not counted.

Abdul Hannan, president of the Carew Sugar Mill Sugarcane Farmers' Welfare Association, said the price of sugarcane is currently Tk 140 per maund (37 kilogrammes) when sold at the mill gate while it is Tk 138 per maund at the procurement centre.

"However, sugarcane cultivation is not possible if the price of sugarcane is not Tk 300 per ounce," he added.

Gias Uddin, general manager (agriculture) of the mill, claimed that there is no problem in the management of their operations. Instead, the closure of state-owned sugar mills has left sugarcane farmers in a dilemma.

This time though, the corporation has taken initiative to provide the required facilities, such as fertilisers, pesticides and training, for farmers.

"So I hope the farmers will soon return to sugarcane cultivation," Uddin said.

For all latest news, follow The Daily Star's Google News channel.

For all latest news, follow The Daily Star's Google News channel.

Comments