Sonali Bag’s production to start within 9 months

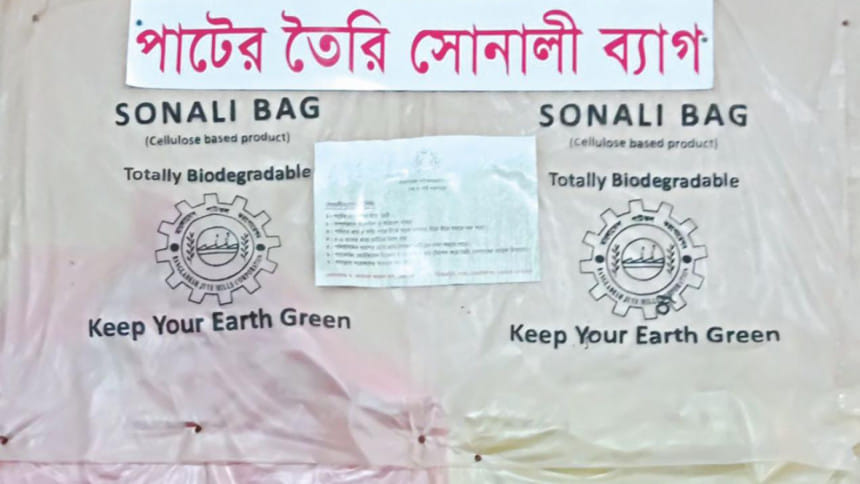

The Parliamentary Standing Committee on Textiles and Jute Ministry today recommended starting the production of Sonali Bag, a biodegradable polybag made of jute polymer, within the next nine months.

It also recommended the ministry and Bangladesh Jute Mills Corporation (BJMC) to finalise the legal documents, regarding the production of the bag, with the polymer’s inventor Dr Mubarak Ahmad Khan within November 30 this year.

The committee came up with the recommendations at its 35th meeting held at Jatiya Sangsad in the capital. The meeting was presided over by Saber Hossain Chowdhury, chairman of the standing committee.

The man behind the groundbreaking technology

Dr Mubarak Ahmad Khan, chief scientific officer at Bangladesh Jute Mills Corporation, the synthesised polymer from jute fibre which can be used to create a kind of bag that works, looks and feels like a polythene bag but without the negative environmental impact.

Dr Khan and his team took six years to complete the process. His hard work has opened brand new avenues for jute, once known as the golden fibre.

Now different types of jute-based packaging bags are being produced on a pilot basis using the polymer at the state-run Latif Bawani Jute Mills in Demra under the “Sonali Bag” initiative of the Ministry of Textiles and Jute which began in May of last year.

Mubarak named his discovery “jute polymer”. It is produced by extracting cellulose from jute fibre.

Tougher than polythene bags, zero impact on climate

Despite being biodegradable, this polymer is water and air resistant and is 1.5 times stronger than polythene. The eco-friendly polymer also decomposes in soil within five to six months as opposed to polythene, which could take several hundred years.

Furthermore, the material is durable and can support more weight than the conventionally used polythene bags.

Despite the government’s assurance to go on a commercial production soon, no visible progress was seen before the signing a memorandum of understanding (MoU) with UK-based Futamura Chemical Company regarding the production early this month.

Comments