EARTHQUAKES AND OUR PREPAREDNESS

In the recent past, Bangladesh has not suffered any damaging large earthquakes, but in the past few hundred years, several large catastrophic earthquakes struck this area. So far, all the major recent earthquakes have occurred away from major cities, and have affected relatively sparsely populated areas. This has limited the human casualty and the economic losses. However, the 1993 Killari, 2001 Gujarat and 2005 Kashmir earthquakes in India and Pakistan has amply demonstrated that inappropriate construction technology may lead to high casualty levels even for moderate earthquakes.

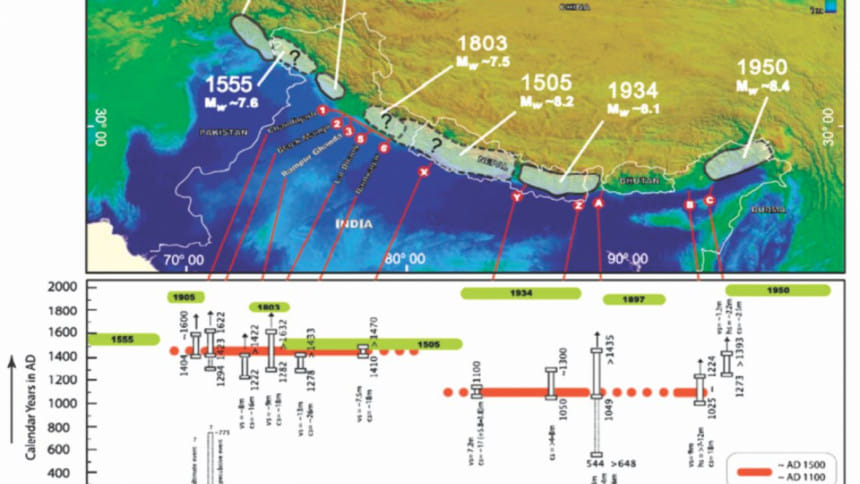

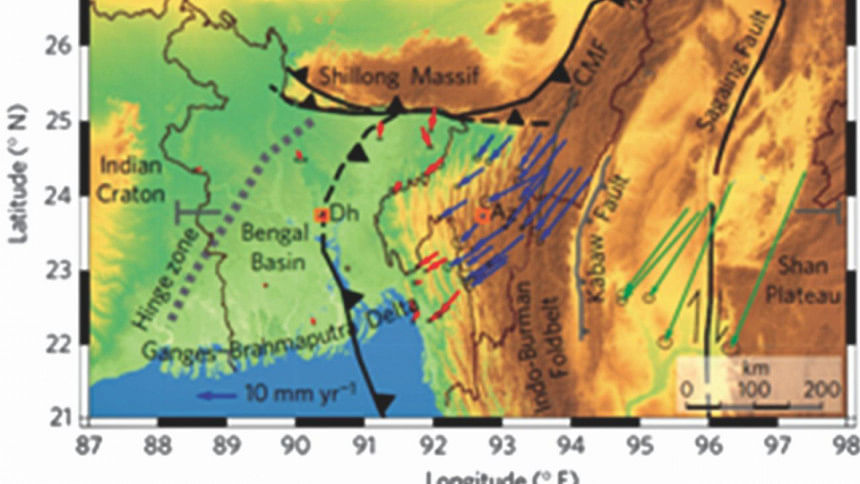

In 1897, an earthquake of magnitude 8.7 caused serious damages to buildings in the northeastern part of India (including Bangladesh) and 1542 people were killed. Recently, Berryman et al. (2014) pointed out that there is high possibility that a huge earthquake will occur around the Himalayan region based on the difference between energy accumulation in this region and historical earthquake occurrence (see Figure 1). More recently, Steckler et al. (2016) suggested that the presence of a locked mega thrust plate boundary under the Indo-Burman ranges represents an underappreciated hazard in one of the most densely populated regions of the world (see Figure 2). The population increase around this region is at least 50 times than the population of 1897 and cities like Dhaka, Chittagong, Kathmandu, Guwahati, Thimpu have population exceeding several millions. It is a cause for great concern that the next great earthquake may occur in this region at any time.

A strong earthquake affecting major urban centres like Dhaka, Chittagong, Sylhet may result in damage and destruction of massive proportions and may have very severe long-term consequences for the entire country. After the 1971 independence, most major urban centres of Bangladesh have grown tremendously due to unabated migration from the smaller towns and rural areas. As a result, the cities have developed in haphazard fashion with little consideration for proper town-planning norms. There is, consequently, a need to be prepared against all possible natural and man-made disasters that are likely to occur in Bangladesh. For this purpose, it is essential to have realistic understanding of the consequences of likely damage in major cities due to different disasters. This will permit rational planning of mitigation efforts in order to minimise effects of these disasters.

The extent of damage to structures and casualty level due to an earthquake in the future can be reduced by the introduction of suitable mitigation measures. These mitigation measures can be categorized as structural and/or non-structural. The structural measures are those that directly influence the performance of building stock through strengthening of code provisions and the prevalent construction practice. Incorporating the appropriate structural mitigation measures can reduce the vulnerability of any building type. The non-structural mitigation measures include improvement in the state of awareness and preparedness before a disaster, land-use control and other government policies, and the infrastructure related to response following a disaster. The non-structural measures help to reduce the severity of casualty levels following an earthquake. In order to reduce the consequences of a major earthquake in the cities of Bangladesh, it is necessary that appropriate structural as well as non-structural measures be undertaken.

Berryman, K., W. Ries, N. Litchfield, 2014. The Himalayan Frontal Thrust: Attributes for seismic hazard, Report produced in the context of the GEM Faulted Earth Project.

Steckler, M., Dhiman Ranjan Mondal, Syed Humayun Akhter, Leonardo Seeber, Lujia Feng, Jonathan Gale, Emma M. Hill and Michael Howe 2016. Locked and loading mega thrust linked to active subduction beneath the Indo-Burman Ranges, Nature Geoscience July 2016.

Ensuring quality in construction is key

Sarwar A Chowdhury

Anwar Group of Industries plans to go for massive expansion in its building material manufacturing units to meet the growing demand for quality construction products that are resistant to earthquakes.

There was a time when many were producing substandard products such as low quality cement and steel in Bangladesh. But those days are gone.

“As competition started building up, competency also started building up and the competition leads us to better products and quality, and we are now producing world class cement and steel,” said Manwar Hossain, group managing director of Anwar Group of Industries.

Given the quality improvement in these two major ingredients of constructions, he does not think that an earthquake will create massive damage in Bangladesh.

He however said still there are some manufacturers who are producing substandard products by using low quality raw materials. “From our association we can only request them not to produce substandard products. But we are not authority. So, the authority should look into the matter,” he said.

Hossain was sharing his views and future plans on the group's building materials division at an interview with The Daily Star recently.

The building materials division of Anwar Group has been dominating the construction industry for the last four decades with a diversified product mix, ranging from cement and cement sheet to mild steel bars, high strength deformed bars, galvanised sheet, uPVC pipe and fittings, and electrical cables.

The group's Anwar Cement now has the production capacity of around 1,250 tonnes per day. “We are planning to almost treble the capacity to 3,000 tonnes per day by December this year,” Hossain said adding that approximate Tk 200 crore will be invested for the expansion project.

Anwar Cement also plans to carry out BMRE (balancing, modernisation, rehabilitation and expansion) in its cement sheet manufacturing unit to increase the production capacity by 25 percent.

Presently, it has production capacity of 7,000 tonnes cement sheet a month that will reach to around 9,500 tonnes after the BMRE, which will be completed by February next year.

“Popularity of cement corrugated sheet is increasing gradually as it is long lasting. The major feature of this item is it reduces the temperature in summer and increases the temperature in winter,” said Hossain.

Anwar Ispat is another building material manufacturing unit that produces graded rods from billets. The existing production capacity of Anwar Ispat is now around 14,000 tonnes per month that will be increased to 30,000 tonnes per month by January next year.

Around Tk 300 crore will be invested for the expansion, said Hossain, who joined the family owned business group in 1993 soon after completing his MBA from University of New Hampshire, USA.

“After expansion, the plant will be a state-of-the-art one and it can be run by a remote control even through a mobile phone. We will be the first one to run such a sophisticated technology, which is a mix of German and Italian,” he said.

A-One Polymer, another entity of Anwar Group, produces premium grade uPVC pipe, fittings, Teflon tape and other plumbing products. The unit is recording over 30 percent growth during the last 3-4 years.

“But we cannot tap the full potential due to unavailability of gas and electricity,” Hossain said adding that they will focus on optimising the existing production capacity in A-One for next two years. “Then we will go for expansion and diversification.”

About the economy, he said the economy is going well. Contribution of rural economy is increasing and also playing a big role in the economic progress.

The remittance or the wage earners' contribution is playing the leading role in the rural economy. “The non-resident Bangladeshis should be given proper recognition and respect,” he said.

However, he said, the infrastructure weakness still remains as the major barrier for investment in the country.

Bureaucracy and bureaucratic attitude towards industrialists is another major obstacle. “Rifts between bureaucrats and industrialists are widening gradually, instead of narrow downing it,” he said.

A friendly business environment is not creating due the superiority attitude of bureaucrats towards the businessmen, he said adding that the mindset should be changed.

Anwar Group, which employees around 12,000 people, also carries out CSR (corporate social responsibility) programmes through Anwar Group Foundation on child education, women health, health and housing to the poor.

Better ingredients, better safety

Sarwar A Chowdhury

KSRM, a Chittagong-based leading steel maker, plans to double its production capacity by setting up its maiden billet manufacturing unit, as the demand for quality rods is increasing.

“We are going to run an overhaul in our factory. After completion of the overhauling that may take some 20 days, we will go for installation of the billet production unit,” said Md Ashfakul Islam, head of market research and development wing.

KSRM now produces rod from imported billets. It is expecting to start the production of billet, a raw material for steel and steel products, by December this year. “Our production capacity will be doubled then,” he said.

The steel maker, which factory is located in Sitakunda of the port city, now produces 4.5 lakh tonnes of graded rods per annum. After billet production, the total capacity will reach to 7.5 to 8 lakh tonnes per year.

Billet, formally known as bar stock, is a common form of raw purified metal, which after processing gives way to steel that can be sold on in markets.

Steel, rod and steel products manufactured from billet is the best, as it maintains the yield strength of the products, Islam said.

Asked about the investment for the new project, he said it can be estimated after the factory overhauling.

He was sharing his views and future plans of the company at an interview with The Daily Star recently.

People are looking for graded and quality rod, which is an essential material in the construction industry as well resistant to earthquakes, he said.

However, he said, it's not only the steel or steel product to resist the impact of earthquakes. “It's the totality; perfect and accurate combination of each materials that will be used for construction,” he said.

For example, steel and concrete mixtures both are equally responsible for a good and strong structure. “Any weakness in any of the two ingredients may make the structure vulnerable,” he cited.

Engineers' expertise, proper design and implementation, and supervision are also responsible for good and strong structure that can be resistant to earthquakes, he said.

“If the demand for quality product is not increasing, we may not expand our businesses,” he said, adding that Bangladesh's per capita steel consumption is only around 30kg, which is one of the lowest in the world.

Per capita steel consumption in India is over 55kg and in European countries it is more than 300kg, he cited.

KSRM, an entity of Kabir Group of Industries, started its journey in 1984 under the name of Kabir Steel. Since then it was producing 40 grade rods from ship breaking scraps. It started production of 60 grade rods in 2003 and 500W rod in 2008 from imported billets.

It is now one of the largest rolling mills in Bangladesh with a market share of around 30 percent. The company employs around 1,200 people.

The local requirement for steel in Bangladesh is around 40 lakh tonnes per year.

For all latest news, follow The Daily Star's Google News channel.

For all latest news, follow The Daily Star's Google News channel.

Comments