RICE FARMING: A green way to cut cost

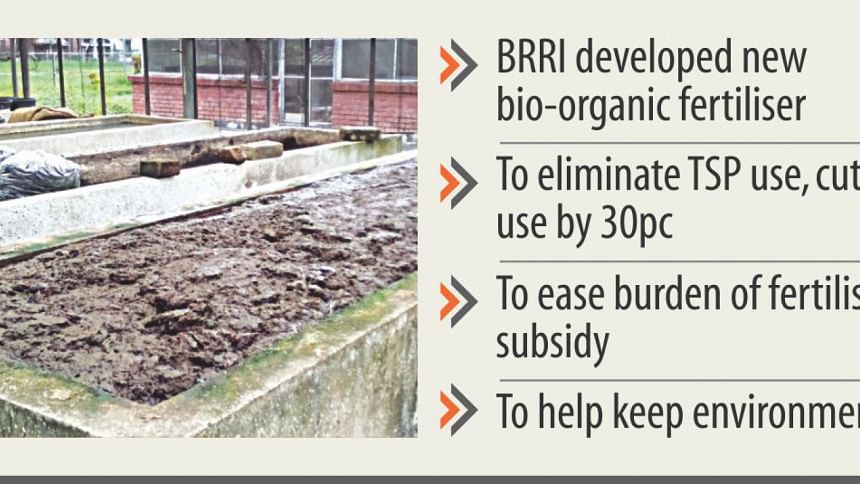

Bangladeshi scientists have developed the perfect blend of decomposable waste, biochar, friendly bacteria and rock phosphate to make two most-used chemical fertilisers in the country's paddy fields largely unnecessary.

A group of soil scientists at the Bangladesh Rice Research Institute (BRRI) yesterday said use of the newly developed bio-organic fertiliser would eventually eliminate 100 percent usage of triple super phosphate (TSP) and reduce urea usage for rice production by 30 percent.

Not only would this help reduce the use of chemical fertiliser, it would significantly cut the government's yearly fertiliser subsidy of Tk 9,000 crore.

It would also help keep the environment clean and green as it would use kitchen waste and cut down carbon emission.

The Soil Science Division of BRRI successfully field-tested the efficacy of this bio-organic fertiliser on paddy in all three rice-growing seasons -- Boro, Aus and Aman.

The tests were done over the last one year at BRRI's compound and the fertiliser is now on trial at farmers' fields in Barisal, Patuakhali, Rajshahi and Kishoreganj.

Umme Aminun Naher, a BRRI principal scientific officer (PSO) and mastermind behind the bio-organic fertiliser, told The Daily Star yesterday that the blend has 10 beneficial bacteria.

About 15 percent of it is biochar (charcoal used as a soil amendment) and five percent rock phosphate, she said, adding that the rest was decomposable household vegetable waste.

She said their trials had shown that the use of bio-organic fertiliser did not have any impact on rice yields and was at par with production level achieved through chemical fertiliser usage.

Naher pointed out that the fertiliser would help reduce carbon emissions. Greenhouse gasses are emitted during chemical fertiliser production and its use, she said.

Research revealed that the production of one kg of urea and TSP fertiliser emits about six kg of CO2 in the air, said the Unesco-ISTIC (International Science, Technology and Innovation Centre for South-South Cooperation) award-winning scientist.

She said, "We are using the same rock phosphate, which is a key ingredient in TSP, but in our process the beneficial bacteria make the rock phosphate soluble. Other bacteria that we are using help compost waste, fix nitrogen from the air and help the paddy plant grow."

The biochar is produced by burning rice husk, she added.

Neither Naher nor Jatish Chandra Biswas, the head of the BRRI Soil Science Division, could give a clear idea on the cost of the fertiliser.

They, however, said the cost of production should be much lower than chemical fertilisers as "we are using household wastes, cheap biochar and bacteria and little amount of rock phosphate, which is available in the market for Tk 5 per kg".

They said the fertiliser would add organic matter and beneficial microbes to maintain soil health. Soil quality would increase with direct application of carbon via biochar.

Research findings indicate that application of chemical fertilisers for a long time decreases the populations of free-living nitrogen fixing bacteria, organisms that solubilise phosphate as well as other beneficial bacteria.

Md Imran Ullah Sarkar and Afsana Jahan are the two other soil scientists of the BRRI team that developed the fertiliser after several years of research, lab tests and field trials.

Jatish told The Daily Star that to move forward with the product, BRRI would first make a patent application. Once they had the patent, they would provide interested enterprises with the technology so that the fertiliser reached all farmers in the country.

The decomposing process of the waste, bacteria, biochar and phosphate would generate a considerable amount of biogas and people would be able to tap into it, once it is produced commercially on a large scale, he said.

BRRI Director General Md Shahjahan Kabir told The Daily Star yesterday that as a first step, BRRI would soon approach the Gazipur City Corporation to go for bio-organic fertiliser production.

"We are (BRRI headquarters) located in Gazipur and we will approach the local city authorities to make the best use of the decomposable waste collected each day. That will have a demonstrative effect on other places in the country," said Kabir.

For all latest news, follow The Daily Star's Google News channel.

For all latest news, follow The Daily Star's Google News channel.

Comments