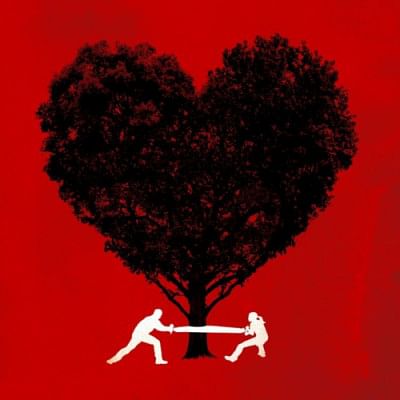

Labour of Love

Ever since 1996, your columnist has been in business. She runs a company that has multiple businesses which once grew from one core business of exporting readymade garments years ago.

When she first engaged in the business, big factories didn't exist; small ones with four to six lines of production capacity were considered significant players. That was a world of quotas and export restrictions. That was a world, where cell phones had just come in, and the net was barely gaining popularity. That was a time when we still waited for faxes to come. Delays of 15 days were taken for granted and if we ever had floods or unrest, most of us would send the pictures and clippings to our buyers and wait for a sympathetic response. That was an era where we dined with our buyers, called them by their first names, and became friends. Business, after all, was a personal matter where faces across the table mattered.

Ever since 2010, our story has had only one tag word: Growth.

In three decades, we have continued to grow at an exponential rate. More specifically, within the last decade or so, our exports have shot up from USD 12 billion to USD 30.61 billion. More factories have sprung up with ever increasing, elastic, flexible production capacities. Production planning has shifted from the tables of the owners to highly sophisticated screens that tell us about what's happening on the factory floor by the hour. We no longer use an eraser on our ruled notebooks with binders to change our production schedule or our delivery dates; we now use the machine to tell us when we can possibly finish production and generate an alert when we run behind our time and action calendar. Our digital lives are marked with red dots, red lines that warn us of our impending failures and when they turn green, we breathe in ease and look forward to a restful night.

The narrative from post 90s has altered. We now speak a language of productivity, calculating minutes, tracking non-performing times. We watch our factory floors on our phones, and monitor our output in the most scientific manner. As a result, Bangladesh today has the most modern, compliant manufacturing facilities in the world. Many of our factories are green and many can safely demand the label of excellence by any global standard from any global brand or retailer.

This transformation has come through a tale of self-discovery through the last two decades or so.

And yes, our story is linked to people; our logic is linked to labour.

From the minimum wage of Tk 1,662.50 way back in 2006, down to the last minimum wage 2018 being set at Tk 8,000, the discussion has always run on a negative strain. Throughout the journey, while manufacturers have constantly argued against just naming the lowest grade as the only mentioned wage in any business discourse, critics have used the lowest salary grade as a flash card to form a global narrative against our trade. The higher grades are rarely discussed and the better stories mostly remain under the radar.

Do good stories usually make their way through the jungle of propaganda? Unfortunately no.

Over the past decades, workplace accidents led to growing demands for improved post-disaster reconstruction and recovery efforts. Throughout all this, Bangladesh made significant progress in its efforts at improving emergency response and post-disaster rehabilitation and recovery.

Post-2013, with businesses focusing on structural, fire and electrical safety, a lot has been achieved. Buyers have continued to source from Bangladesh and our quantities have grown in a considerable manner. Yet, while the sector thought that all was good and shining, the minimum wage debate has once again hit the sector. A new gazette with the new minimum wage was published at the end of November. While there was no immediate reaction, and while the day of the national election approached, suddenly a complaint of one or two grades not having been adjusted properly began to hit a few areas and in no time, a more violent picture began to suspiciously surface while the nation prepared for polls. In the last couple of days, most of our workers have been compelled to leave our factory floors and join processions gaining momentum right outside our factory gates. In spite of the gates being secured, there have been cases of extreme violence, and destruction of assets leading us to wonder about how and why have the manufacturers fallen prey to a negative narrative surrounding a sector that we have spent all our lives building.

While the reality of Rana Plaza hit us hard, we invested all that we had in addressing the image deficit of the sector. While we reeled from the tragedy, we grew closer to our workforce, accepted hikes, reforms, and any prescriptions that came our way. And yet, in spite of the orders growing in number, in spite of the export volume steadily climbing, in spite of a workforce committed to work in the factories, we are currently witnessing the most unfortunate spate of violence that is totally unacceptable and shocking. This must stop. If we see our own workers taking to the streets, let us get to the bottom and identify the instigators as ominous, perhaps familiar shadows lurking around our workplaces. Let us all remember that Bangladeshi manufacturers have not invested their toil and sweat to watch the sector go up in flames…

Post 2013, majority of us have focused on rebuilding our spaces based on the basic premise of an improved relationship with labour. Machines may help us plan and predict our output, but the logic around labour must win over all considerations. While manufacturers continue demanding better prices, and while brands and retailers try to use their defence of referring to the global competition and decreasing margins, let us just remember two things simple enough to acknowledge, uphold and practice:

There's no alternative but to improve the narrative around owner-worker platform and there's no alternative but for us to bargain for a fair price from our buyers.

And while we ask for a fair price, we need to remind ourselves of the following:

1) We have capacities that no other country can grow overnight.

2) With the global trading market forecasted to go up from USD 454 billion in 2017 to USD 600 billion by 2020, Bangladesh stands a fair chance of pushing her 6.46 percent and chasing the 34.86 percent Chinese figure of the global market share.

Meanwhile, let's also caution ourselves and address the challenges:

1) Vietnam has a claim of 5.89 percent share of the global market with far fewer number of factories than ours. Thus, we need to add value addition to our products.

2) With Turkish depreciation of close to 300 percent, Sri Lankan up to 45 percent, Indian rupees up to almost 49 percent, our export challenges are way bigger with an appreciation percentage of .04 percent over the last 5 years or so.

3) Efficiency level at our end is stuck at around 45 percent while Sri Lanka has crossed 70 percent, China almost 68 percent

4) Most of all, prices from European Union have been going down over the last couple of years. The import price of EU was USD 1589/100 Kg in 2012, dipping to USDD 1497/100 Kg in 2013, going up to USD 1575 in 2014, USD 1561 in 2015, USD 1508 in 2016, USD 1525 in 2017 and finally decreasing to USD 1520 in 2018.

It's natural to expect exports from Bangladesh to go up; but it's equally important to remind ourselves that this vicious cycle of violence and the negative stories brewing at every corner of our export ride can only be put to rest if we are more mindful while dealing with labour. Labour, after all, has a logic of love, which can't go unnoticed or unaddressed.

Dr Rubana Huq is the managing director of Mohammadi Group. Her Twitter handle is @Rubanah.

Comments