Another Eid comes, leather estate is still ill-equipped

Bangladesh's two-decade-long quest to put in place a system that can process 100 per cent of rawhides generated during Eid-ul-Azha continues owing to the lower-than-required capacity of the Savar Tannery Industrial Estate (STIE).

As a result, the authorities have decided to treat the animal skins to be collected in phases in order to tackle oversupply, if any.

The estate will process the rawhides collected from Dhaka in the first week after Eid, which falls on Thursday, since traders in and around the capital city are well-positioned to bring skins to the facility fast.

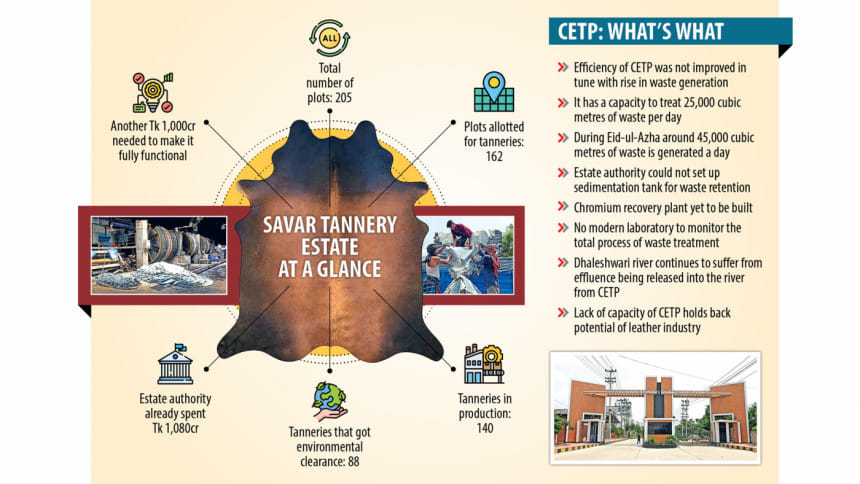

Currently, the central effluent treatment plant (CETP) at the STIE has the capacity to treat 25,000 to 30,000 cubic metres of liquid waste. But during Eid-ul-Azha, the generation of waste climbs to 45,000 cubic metres as the number of rawhides collected shoots up.

In Bangladesh, Eid-ul-Azha accounts for half of the rawhides that tanners collect throughout the year. About one crore animals were sacrificed last year.

Around 1.30 crore animals are ready to be sacrificed this year, said Aftab Khan, president of the Bangladesh Hide and Skin Merchants' Association, recently quoting data from the livestock ministry.

The estate has been set up to help the country's tannery industrial estate get rid of pollution stemming from rawhide processing. But it has not made significant progress in putting in establishing a fully functional liquid and solid waste management, a salt purification system and a common chromium recovery unit even though the work to construct the STIE started in 2003.

When the estate and the CETP were planned, the systems and units were supposed to be set up in the initial stage of construction, but they were later dropped, said Mustak Ahmed, managing director of Dhaka Tannery Industrial Estate Waste Treatment Plant Company (DTIEWTPC), which runs the facility.

Steps have been taken to address the issues, he said.

The government has spent already Tk 1,080 crore to establish the Savar Tannery Industrial Estate but Ahmed said another Tk 1,000 crore was needed to make the facility fully functional.

Kabir Hossen, an official of Nabarun Tannery, said his company has targeted to buy 10,000 pieces of rawhides. "If the price is low, we will double the number."

Failing to process the precious rawhides in line with global standards is already proving costlier for Bangladesh although the leather industry is one of a few sectors in Bangladesh for which raw materials are locally available, which offers the scope for a huge value-addition and thus earning more foreign currencies.

But owing to a lack of global recognition, Bangladeshi suppliers have to export leather mainly to China at rates that are much lower than the going rates in the international markets. What is more, finished goods exporters have to import rawhides from compliant factories in other countries to ship products to developed markets.

In the July-May period of the current fiscal year, Bangladesh exported leather and leather goods worth $1.12 billion, registering a year-on-year growth of 0.42 per cent. But industry people say the industry has the capacity to be a multibillion-dollar sector.

Another drawback of an absence of a fully functional CETP is the nearby Dhaleshwari river is being polluted, meaning the principal goal of shifting tanneries from Dhaka's Hazaribagh to Savar has remained unachieved in the first place.

The tanneries were relocated in 2017 with the hope of reviving the Buriganga, which bore the brunt of pollutants released by the factories. The tanneries might have been shifted, but their processes are still polluting rivers.

During a visit to the estate area on Monday, one of the correspondents talked to Mohammad Nasir, a fisherman.

He said he had earned a living by catching fish in the Dhaleshwari for 30 years.

"During monsoon, fish seems okay. But during the other times of the year, fish smell of kerosine" he said, adding that he pulls a rickshaw most of the time of the year and occasionally catches fish.

Currently, the CETP takes 53 hours to treat wastes but the standard time should be 72 hours, according to the DTIEWTPC. The biological treatment process takes 25 hours whereas it should be 48 hours as per international practices.

An official of the Department of Environment told The Daily Star that the design of the CETP was flawed and it was set up without a feasibility study. Even the facility does not have any environmental clearance and it has been allowed to operate based on some conditions.

For all latest news, follow The Daily Star's Google News channel.

For all latest news, follow The Daily Star's Google News channel.

Comments