RMG vision: The immediate and the important

It's an era of innovation. It's an era of efficiency. In one part of the world, they are making "smart" jackets, which are creating a microclimate for the wearers, by using carbon fibre heating pads, and are also using Amazon's smart assistant Alexa to even pre-heat the jacket before the consumers are putting them on. And yet, in another part of the world, most of us are spending most of our time battling the immediate in place of the important. What's more needed for our readymade garment sector? Is it the important or the immediate? Or is it both? Considering the urgency to take the sector to the next level, the "important" might as well be listed:

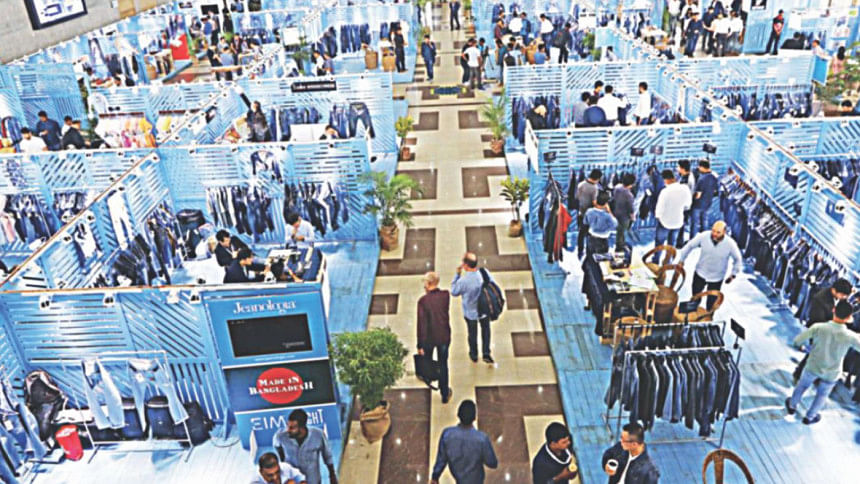

Image deficit and branding

There are negative campaigns abroad that often rock the industry and these must be addressed with caution. It's, after all, time to admit that much has been achieved and much needs to be done in terms of collaborative approaches from all stakeholders including brands, workers' representatives and manufacturers. For us to battle the barrage of international criticism, we need to be more responsive, and readily equipped with substantiated data to address any confusion that may arise from time to time. Sufficient engagement of all stakeholders will then ensure that a lot has been done and that through remediation, the industry is moving on to the next platform of sustainability.

Product pricing

Maybe it's time to call us competitive and not the cheapest. The country's image, so far, has been only about being the supplier of the "cheapest" products. USD 5.86 billion worth of basic t-shirts are exported, followed by USD 5.20 billion worth of trousers with the rock bottom category belonging to value-added ladies' blouses, jackets, cardigans, and a few other categories that haven't even crossed USD 100 million in their individual brackets. While we feel that we can offer multiple products, the faith of the brands in our manufacturing capabilities is at a lower rung of the ladder. Attempts to add value by researching the fast-changing face of fashion and rapidly changing consumer patterns will definitely aid us in determining the next level of production focus.

Wage and productivity

It's perhaps time for all to realise that not all are aware of the low margins of the original manufacturers. Thus, we need to try and attempt to correct that perception through honest narratives and professional lobbying, and we also need to make a clear connection between wages and productivity. The wage-skill grid must be practised to assess the basic efficiency of the workers and wages must be determined accordingly. This would translate into a win-win scenario for all.

Markets and policies

While there are bank-, bond-, port-, road- and infrastructure-related issues to handle within the country, there are also markets and policies that we need to tap into. For example, markets like Saudi Arabia import over USD 3,000 million from the world and yet source only 75.61 million from us at 5 percent duty. Russia imports USD 7,000 million against 5-10 percent and imports only USD 427 million from Bangladesh. China has zero import duty and yet out of USD 7,560 million, only USD 391.64 million is sourced from this country of ours. Brazil and Mexico are the same stories as Brazil imports only USD 158 million out of USD 1,794 million against a duty figure of 35 percent and Mexico with 20 percent duty sources only USD 148 million out of USD 3,775 million of its total exports…

One of the key factors determining our future will be our readiness to respond to international scenarios. While we must position ourselves to a post-Brexit landscape, we must also steady ourselves to bring to table the most critical discussion on a free trade agreement with the United Kingdom. British Prime Minister Theresa May has already shared that India, Canada, China, India, Mexico, Singapore and South Korea are among the countries which are interested on an FTA agreement while the discussions with Australia and New Zealand have also already begun. Thus, it is time for Bangladesh as well to tow the same route.

There are also discussions on Bangladesh getting ready for GSP+. While this graduation is most certainly laudable, we must also consider that the validity of the EU GSP+ would depend on conditionalities, with respect to compliance of non-trade issues, beyond the scope of WTO, TBT, SPS and other agreements, covered under 27 core international conventions.

If the GSP-granting countries (including EU) have signed and are going to sign free trade agreements with India, Pakistan, Sri Lanka, Vietnam, Cambodia, China, Korea, Malaysia, Philippines, Indonesia and others in different combinations, why should Bangladesh lag behind?

Then of course, there's another avenue with the United States opening up. According to OTEXA, the overall increase of export to the US has risen from USD 5.06 billion to USD 5.4 billion in a span of only a year. According to OTEXA, 2018-19 exports are up by 19.92 percent. With a positive turn in economic diplomacy, and with the US-China trade war flaring up, it may be wise to re-approach the GSP issue, in spite of it not including apparel import. The image must be rescued. That's what matters the most.

Sustainability

While post-Rana Plaza ushered in a whole new era of remediation, doubts around sustainability continue to haunt the sector. Somehow the common perception is all about us not wanting to sustain the positive changes and somehow the verdict is always in the favour of us being monitored. Little do we make it known that we have poured in so much investment into our production units that we now can't afford to see all that go wasted. Let this be clearly known: our factories were audited by local engineers who have complete knowledge of the sector now and with the help of well-meaning international brands, unions and development partners, we can sustain our own positions and proceed to self-monitoring, without losing any time.

Innovation to industry: I2I project

This is a world where Artificial Intelligence sits on boards of companies even in Asia. Thus, it's time for low-end manufacturing to graduate to the next level of reskilling so that more jobs can be created to address the intermediate challenges. Pilots could be done to assess the basic needs of the industry and innovation could follow our industry needs. For example, 3D printers may revolutionise the sector. While bio-printing is already being practised, it's perhaps time for us to produce our spares and machinery through advanced technologies as such.

Let's face it now. There's the immediate, intermediate and the important to address. And we have limited time to do so. Thus, it's time to be restless while we approach Bangladesh touching its 50th year in 2021. It's not just going to be a new discourse on export volume, it definitely should also be one of image, innovation, efficiency, pricing, policies and sustainability. All are intrinsically linked to the other and we can't but address them all at one go.

There's no time to wait and there's certainly no time to lose.

Dr Rubana Huq is the managing director of Mohammadi Group. Her Twitter handle is @Rubanah.

Comments