Carbon fibres made from air

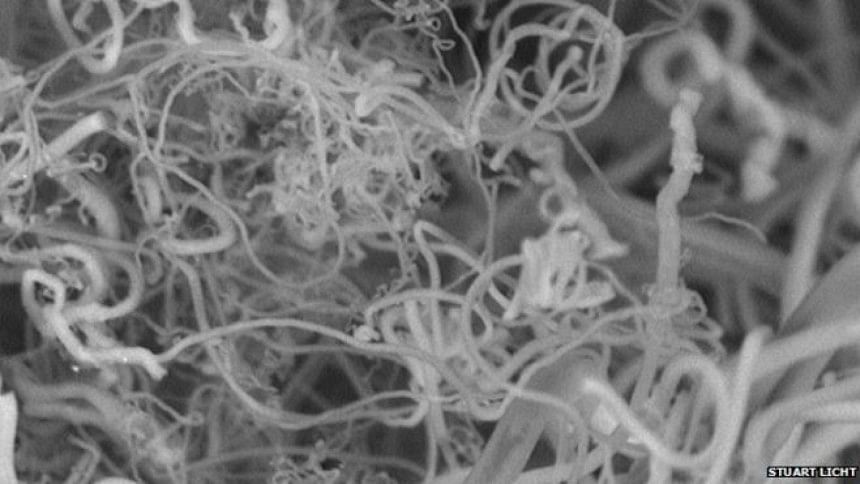

Scientists in the US have found a way to take carbon dioxide (CO2) from the air and make carbon nanofibres, a valuable manufacturing material.

Their solar-powered system runs just a few volts of electricity through a vat full of a hot, molten salt; CO2 is absorbed and the nanofibres gradually assemble at one of the electrodes.

It currently produces 10g in an hour.

The team suggests it could be scaled up and make an impact on CO2 emissions, but other researchers are unsure.

Nonetheless, it could offer a cheaper way of making carbon nanofibres than existing methods.

"Until now, carbon nanofibres have been too expensive for many applications," said Prof Stuart Licht of George Washington University. He was speaking at the autumn meeting of the American Chemical Society in Boston.

Carbon nanofibres are already used in high-end applications such as electronic components and batteries, and if costs came down they could be used more extensively - improving the strong, lightweight carbon composites used in aircraft and car components, for example.

The question is whether the "one-pot" reaction demonstrated by Prof Licht and his team could help to drop that cost.

The idea of turning CO2 from the air into useful products is a popular one, and the field is strewn with many more unfulfilled promises than success stories.

But Prof Licht is confident his design can succeed. "It scales up very easily - the entire process is quite low energy."

He also suggested that the system could provide "a reasonable path to bring down CO2 levels in the atmosphere".

This would involve adopting the reactors on a colossal scale and the idea has raised some eyebrows.

Dr Katy Armstrong, a chemical engineer at the University of Sheffield, said the process was "promising and very interesting on a lab scale" but that Prof Licht's bigger vision might be problematic.

"As they are capturing CO2 from the air, the process will need to deal with huge volumes of gas to collect the required amount of carbon, which could increase process costs when scaled up," she told the BBC.

Dr Paul Fennell, a chemical engineer and clean energy researcher at Imperial College London, said: "If they can make carbon nanofibres, that is a laudable aim and they're a worthwhile product to have.

"But if your idea is to take CO2 out of the atmosphere and produce so many carbon nanofibres that you make a difference to climate change - I'd be extremely surprised if you could do that."

Prof Licht insists it is worth trying.

"There aren't any catches; there's a necessity to work together, to test this on a larger scale, to apply some societal resources to do that."

Meanwhile, other chemists were impressed by the simple fact that Prof Licht's team had produced nanofibres from atmospheric carbon.

Dr Dario Corradini was also at the American Chemical Society meeting, presenting his theoretical work on absorbing CO2 with a similar type of electrochemical cell.

"These cells are relatively inexpensive in terms of energy consumption - it's definitely a realistic approach to producing the nanofibres," he said.

For all latest news, follow The Daily Star's Google News channel.

For all latest news, follow The Daily Star's Google News channel.

Comments