What the auto industry is doing to help during the COVID-19 pandemic

COVID-19 has successfully caused the global economy to come to a standstill. The global car market has taken a nosedive with light vehicle sales in the US alone being dropped by 39%. Car production around the world has been shut down to prevent the spread of the virus, causing many automakers to lay-off thousands of workers and reach out for government loans to avoid bankruptcies. On the other hand, the vast idle manufacturing and mobility capacity of the automobile industry can play a key role in these trying times. Many have stepped up to do their part.

Helping the war effort: Keeping the health works on the move.

Many carmakers have begun to take an active part in the world's defense against COVID1 9, providing the healthcare system with much-needed mobility. In UK, Ford has lent 200 vehicles from its press fleet to multiple organizations including the British Red Cross and UK National Health Service. Jaguar Land Rover lent another 160, including 27 examples of the new Defender. Even Rolls-Royce, the de-facto icon of luxury, has deployed a fleet of 30 limousines to deliver groceries and medical supplies to those in need.

Other companies such as Vauxhall and Nissan have begun offering free roadside assistance to healthcare workers, a move that is mirrored by AAA in the US. US car rental company Hertz has also stepped up to help, offering free rentals to all healthcare workers.

Switching production: Equipping the health workers

As the spread of COVID 19 increased, so did the need for face masks and other Personal Protection Equipment (PPE). This demand soon surpassed the supply, pushing the existing supply chain to its breaking point. Chinese carmaker BYD was among the first to react, switching the production lines at its Shenzen facility to produce face-masks and disinfectants. They soon began making 300,000 bottles of disinfectant and five million masks per day, making the plant world's largest producer of the latter.

As the virus's epicenter moved from China to Europe, the local auto industry was quick to follow BYD's example. Italian supercar maker Lamborghini began producing face shield and mask in their plant in Sant'Agata Bolognese, along with Aston Martin, Rolls-Royce, Jaguar Land Rover, SEAT, and other European carmakers.

Is US, the big three carmakers have also begun their own PPE production, with General Motors (GM) reopening its closed Michigan just to build more facemask. Small shops have also pressed themselves into action, such as JK Automotive Designs in Stoneham, Massachusetts who are churning out 45 face shields every ten minutes.

In India, Mahindra & Mahindra has also begun producing face shields at its two-wheeler manufacturing plant at Pithampur, Madhya Pradesh.

Helping patients breathe: ventilator production

As the healthy people of the world scrambled to protect themselves, those who are already infected faced with a new shortage. The COVID-19 is a severe acute respiratory syndrome, meaning it fills the lungs with fluid and debris which makes it almost impossible for the victim to breathe naturally. This is where a ventilator, a machine that provides mechanical ventilation by moving breathable air into and out of the lungs, becomes a critical part of treatment. The demand for the device was quite low before the outbreak, and the handful of companies that makes them found themselves with mountains of orders that are impossible to fulfill on time. The automobile industry found themselves to be the unique solution to this crisis, being able to supplement many of the ventilator components with off the shelf automobile parts. Electric car pioneer Tesla fully embraced this idea, and are working on a ventilator prototype build almost exclusively out of Model 3 components. Others took a more pragmatic approach, such as Ford who partnered with General Electric Healthcare to build the Model A-E, a quick setup ventilator that can operate without the need for electricity. GM also took a similar approach partnering with Ventec Life Systems and begun setting up a facility in Kokomo, Indiana for ventilator production.

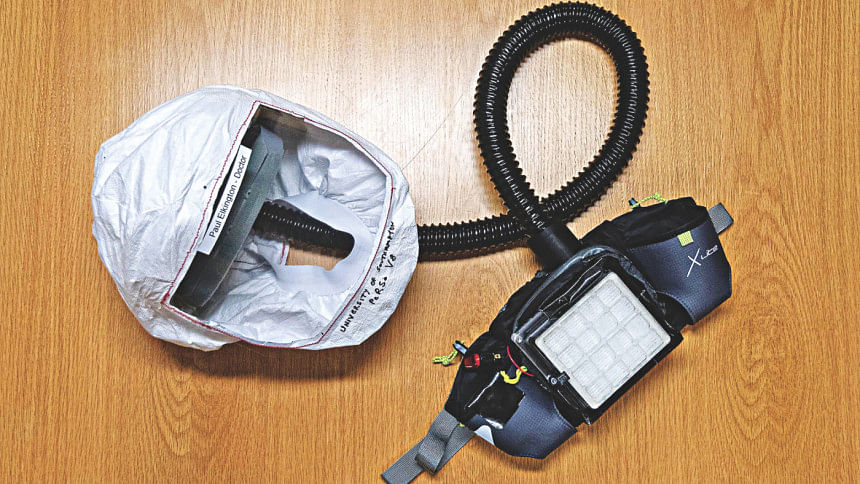

Across the pond, Spanish carmaker SEAT has begun producing their emergency OxyGEN ventilator, which uses a repurposed a windshield wiper motor to operate the device's pump. While UK-based Formula One teams like Mercedes-AMG F1, Red Bull F1, Williams and McLaren started "Project Pitlane". An initiative that connects the teams with engineers and healthcare workers to facilitate rapid prototyping and fast-track the production of medical devices. So far, their Continuous Positive Airway Pressure (CPAP) device was approved by the UK Medicines and Healthcare products Regulatory Agency while McLaren F1 designed personal respirators for health care workers are undergoing testing.

For all latest news, follow The Daily Star's Google News channel.

For all latest news, follow The Daily Star's Google News channel.

Comments