Steel 'Intensity' and economic growth

Steel has enabled our modern way of life. It is the material which engendered urbanization and industrialization and enabled human societies to move out of a predominantly agrarian way of life to the modern city dwelling life style. It has helped lift societies out of poverty, spurring economic growth, and continues to do so around the world today.

Iron, steel's precursor, fueled the industrial revolution starting in 1750, enabling manufacturing equipment in factories and rail transport. Modern steelmaking was developed 150 years ago with the invention of the Bessemer process, in Germany, which allowed the affordable mass-production of steel (an iron alloy). This set off a second industrial revolution, and sustained economic growth.

Machineries made of steel enabled mass production of goods and replaced the artisan and guild system of manual manufacture. The massive use of steel in ocean going vessels and railways created the modern commercial world as goods manufactured in one part of the world could be safely and cheaply transported to be sold in another part of the world.

Steel is one of the most common materials in the world. We rely on it for our housing, transport, food and water supply, energy production, tools and healthcare. Nearly everything around us is either made of steel or manufactured by equipment made of steel.

The steel industry employs more than 2 million people directly around the world, with a further 2 million contractors and 4 million in supporting industries. Considering steel's position as the key raw material supplier to industries such as automotive, construction, transport, power and machine goods, the steel industry is the source of employment for many more hundreds of millions of people.

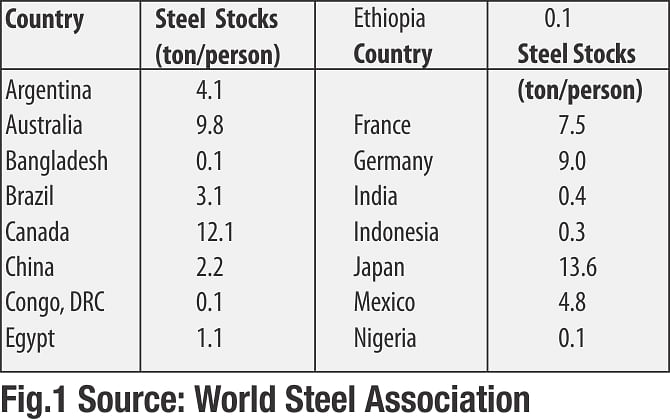

Steel is inextricably linked with economic growth and prosperity, as shown in Figure 1. This figure estimates stocks of steel per person, of different nations of the world. As a nation's per capita GDP increases they build up their stock of steel as well.

The table in Fig.1 has to be understood in the context that all of us are indirect 'consumers' of steel. Steel is the invisible skeleton holding us safely together in our high rise concrete houses. A well built concrete apartment of 1500 sft in Gulshan or Dhanmandi has around 7 tons of steel reinforcement which the owner or renter 'consumes' indirectly. His children in school too 'consume' steel indirectly as he does in his office. Similarly a person riding a vehicle 'consumes' steel. The steel in a nation's infrastructure, its ports, airports and bridges and other public utilities is consumed collectively by all its citizens.

According to Fig.1 Bangladesh has a long way to go to attain steel intensity as the vast majority of its population still resides in rural habitations and infrastructure still does not cover the majority of the population. By contrast advanced economies, such as Australia and Canada have much larger steel stock per person, 9.8 and 12.2 tons per person respectively, as its housing, urban centers, and infrastructure is very highly developed.

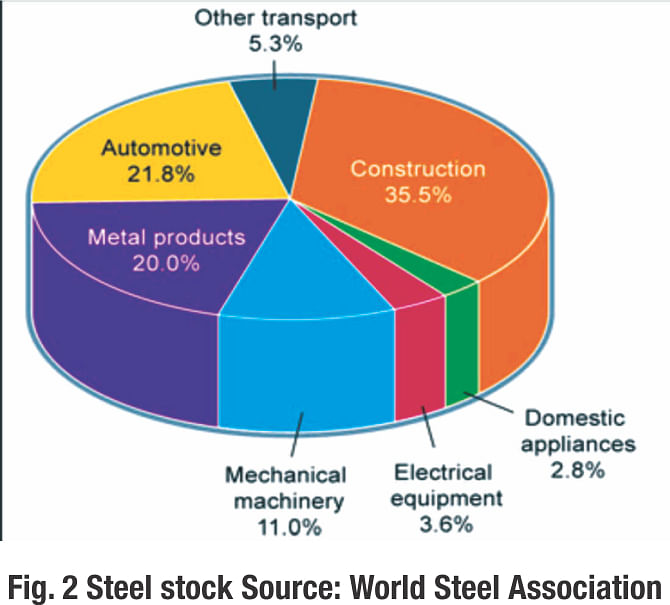

The pie chart Fig.2 shows the breakup of the steel asset of India and China the two emerging global economic powerhouses. This is typical of steel use in most nations in Asia and other developing nations. Construction which includes Housing and Infrastructure obviously has the largest share.

The chart reveals the ubiquitous nature of steel in the modern world. Steel is present in most modern day articles of use but the steel content is hidden. For example a country is a big user of consumer durable goods such as automobiles and refrigerators and washing machines all of which has very high steel content, but not readily apparent.

In Bangladesh most construction steel can be traced to local production, which is roughly 4 million tons per annum of long products, most of it in reinforcing steel, commonly known as M.S. Rods. Another 0.7 million tons of corrugated galvanized roofing sheets commonly known as C.I. sheets are also produced locally. Steel stock from capital goods such as machineries and transportation vehicles are entirely imported.

The total steel stock of the nation is abysmally low at 0.1 ton per person. To attain the steel intensity of India at 0.4 ton per person our apparent steel use and production must increase by a factor of 4 times This shows our country needs much more investments in infrastructure and utility facilities, which would mean more expressways, bridges, power plants, mass railway networks, ports and airports etc. in the public sector. Investments in the housing sector by the private sector will drive demand for construction steel. Construction steel will dominate Bangladesh steel production for many more years in the future.

The writer is Head, Product Development, BSRM Group.E-mail: [email protected]

For all latest news, follow The Daily Star's Google News channel.

For all latest news, follow The Daily Star's Google News channel.

Comments