RMG sector: Lessons for the future

The formation of Accord and Alliance in 2013 and their activities for workplace safety in the RMG sector have led to important organisational learning for Bangladesh. For the first time, stakeholders of the RMG value chain have experienced new forms of compliance assurance. First, brands/retailers/buyers and international trade unions are involved in ensuring workplace safety at the manufacturers' end; second, local entrepreneurs now have as a requirement high level of safety standards and maintenance at their own factories; third, local public agencies have appreciated the gaps in monitoring and enforcement mechanism that they follow and also the requirement of improvement of their process; fourth, workers of RMG enterprises have been able to understand the safety-related issues and concerns and how to respond in case of emergencies in the factories.

Such organisational learning in Bangladesh's RMG industry has encouraged global brands/buyers to replicate those in other apparel manufacturing countries. The key issue is, how do we institutionalise such learning with a view to develop an effective monitoring and inspection mechanism in the future?

After five years of operation, both the initiatives have entered into a transitional phase as the initiatives of Accord and Alliance are going to end in 2018. Given the remediation works that remain in factories, both Accord and Alliance will extend their timeline to complete their work; however, Accord is willing to extend their operation beyond the limited time period but Alliance is not willing to extend their contract. In 2017, a new body was formed under the Directorate of Inspection of Factory Establishments (DIFE) of the Ministry of Labour and Employment (MoLE) with a view to oversee the progress of remediation-related activities of, initially, factories under the National Initiatives and later other factories including those under Accord and Alliance. The creation of a Remediation Coordination Cell (RCC) is important in order for a public agency to take over charge; at the same time, this set-up is expected to deliver the services maintaining the quality and standards.

The point is, how quickly can the newly formed RCC adapt to the organisational learning accrued through Accord and Alliance? And will it be able to deliver the expected level of services and thereby become an effective monitoring agency in Bangladesh?

LESSONS LEARNT FROM ACCORD AND ALLIANCE-LED INITIATIVES

During the last five years, a number of unique features have been revealed through the private sector led initiatives of Accord and Alliance. These include, among others, formation of the private entities with the participation of major brands, retailers, buyers and international trade unions for monitoring safety standards of a major sourcing country, harmonising national rules and regulations concerning workplace safety of Bangladesh within a short time, setting up

standard operating procedure (SOP) for monitoring and inspection, and review and follow-up of remediation work of factories on a timely basis. It is to be noted that fire, electrical and structural safety concerns of RMG factories are the key areas of monitoring and review under these initiatives. The safety concerns of backward linkage activities of the RMG enterprises (such as textiles, accessories, etc.) had been excluded from monitoring and inspection which also need to be taken into due consideration. Besides, both the initiatives have prepared corrective action plans (CAPs) for each of the factories based on the problems identified in the factories and made them public through their websites. The progress of remediation-related work of each factory has also been made public. Both the initiatives made timely review of remediation-related work and based on the progress put necessary pressure on factories for timely completion of their remaining work; in extreme cases where factories were unable to comply with target level of remediation work, business ties with those factories ended. On the other hand, factories that successfully completed the remediation-related work received a “letter of recognition” from the private initiatives.

It is a fact that the method followed by private initiatives has to get a positive nod (though informal in nature) from the stakeholders, particularly employers, which isn't always a smooth process. The first step of Accord and Alliance was to consolidate national rules and regulations related to fire, and electrical and building integrity. Based on the national rules and regulations, including Bangladesh National Building Code Act, Bangladesh Labour Act 2006 and other national rules, a comprehensive document was prepared. In case of insufficiency in local rules, both Accord and Alliance took support from international rules/guidelines which further strengthened the overall safety standards. However, this inclusion in the operational guideline was not welcomed by entrepreneurs because of the requirement of huge additional investment in order to comply with the new standards. However, entrepreneurs ultimately accepted these new standards and made the necessary investment for improvement of compliance standards.

Both the initiatives follow almost a similar type of standard operating procedures for inspecting factories such as inspection checklists, standard level of compliance of different safety measures, testing requirements, timeline for remediation, reporting of problems, public reporting of non-compliance, review mechanism, notice period, level of warning and cancellation of contractual ties in case of non-compliance, etc. Entrepreneurs were initially quite apprehensive about public reporting of non-compliance of their respective factories fearing adverse effect on their reputation; however, such reputational risk of public reporting did not happen, rather employers actually benefitted through reporting of their compliance-related information. Most importantly, such public reporting of the state of compliance of inspected factories has ensured transparency about the initiatives and made the concerned stakeholders more accountable.

According to the last available report of Accord and Alliance, a significant number of problems have been remediated by the factories. In case of Accord-inspected factories, 85.4 percent of electrical, 76.4 percent of fire-related and 65.4 percent of structural problems have been addressed while the respective shares in case of Alliance-inspected factories are 89 percent, 85 percent and 78 percent, respectively. In both cases, factories are relatively slow in remediating structural problems because of difficulty in addressing their concerns. Besides, Accord and Alliance have taken initiatives to increase awareness among workers about the safety standards of factories by setting up safety committees at the enterprise levels as well as introducing hotline for workers. These initiatives have provided a strong supplementary role in addressing the safety concerns at the factories.

INSTITUTIONALISATION OF ORGANISATIONAL LEARNING THROUGH ACCORD AND ALLIANCE

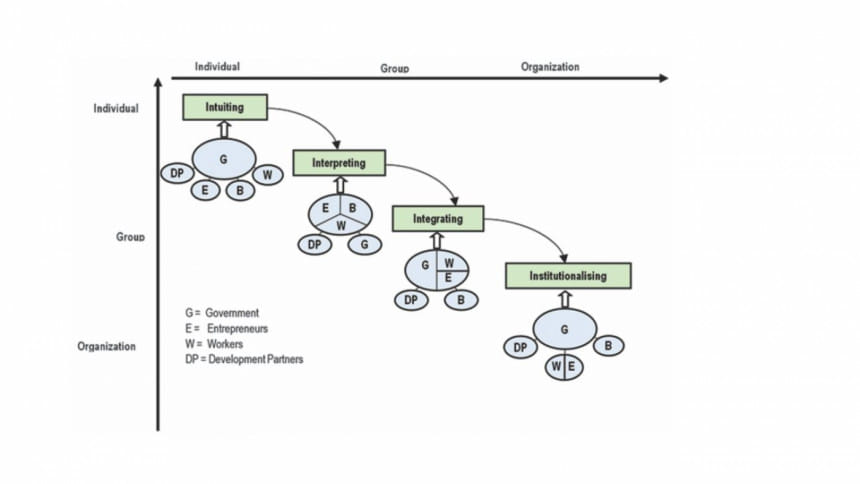

Such detailed organisational learning through the initiatives of Accord and Alliance has strong elements that can be institutionalised with a view to make them sustainable. Theoretically, organisational learning is a cyclical process through which knowledge that is learned on an individual or group level is objectified on the organisational level, institutionalised and embedded in the organisational memory (Wiseman, 2007). There is a 4-I Framework of organisational learning (developed by Crossan, Lane and White, 1999) which identifies four main processes including 'intuiting', 'interpreting', 'integrating' and 'institutionalising'. Figure 1 presents different steps of organisational learning and role of stakeholders in different steps.

Analysis of the activities of Accord and Alliance reveals that their completed work resembles the first two phases of institutionalisation— 'initiation' and 'interpretation'. The third phase of this process, i.e. 'integration' needs to be initiated which will be followed by the final phase i.e. 'institutionalisation'. With the end of the initial commitment period of Accord and Alliance and thereafter, initiation of the work of Remediation Coordination Cell (RCC) under the DIFE of the MoLE, the process of integration has been started. This specialised cell will work in the transition phase and meet the requirement. The objective of this Cell initially would be to monitor and inspect and review the progress of remediation-related activities of factories earlier inspected under National Initiatives. The Cell will gradually take over the responsibility of factories under Accord and Alliance-led initiatives and ultimately take charge of inspection-related activities of all industrial enterprises in Bangladesh.

In this context, a number of issues need to be taken into due consideration with regard to the capacity of the public agency to inspect and monitor factories as per the standards set by private initiatives: a) Is there adequate technical human resource, and organisational capacity to monitor, inspect, review and ensure compliance according to global standard by public agencies? b) Will buyers/brands accept the inspection reports to be prepared by the local agencies and continue their businesses with local suppliers? c) Should the private agencies (such as Accord or other private agencies) be involved in facilitating the monitoring work of the public agencies, and what kind of arrangements would work well in this regard? d) In case of a transition period, what should be the arrangement between public and private agencies in dealing with the current and future safety concerns of RMG factories?

ARRANGEMENT FOR TRANSITION PERIOD

The ultimate objective should be to strengthen the monitoring and inspection capacity of public agencies. Given the limited capacity in terms of human resources, technical issues and database management, public agencies need to prepare themselves under a targeted timeline with specific objectives and action plans. The RCC has been formed with the long-term objective to inspect factories maintaining global standards. Hence RCC needs to be equipped with competent human resources, technologies, skills, logistics, testing facilities, adequate resources and database management system.

Despite strengthening RCC, it is not technically feasible to monitor and inspect all factories by this lone agency as this would require large-scale investment in RCC. Considering the level of competency available at the private sector, it would be better to undertake their services under the arrangement of public-private partnership (PPP) where a public agency would be in charge of overall supervision of the monitoring process and private agencies accredited by the public agency would undertake monitoring and inspection-related work. Such an arrangement will ensure quick monitoring, better reporting and more transparency.

Besides, it is important to integrate the brands and buyers in the process of compliance assurance. The ultimate objective is to ensure workers' safety and security initially in export-oriented sectors and gradually in other sectors which have jobs with a degree of risk.

Dr Khondaker Golam Moazzem is Research Director at the Centre for Policy Dialogue (CPD).

For all latest news, follow The Daily Star's Google News channel.

For all latest news, follow The Daily Star's Google News channel.

Comments