Lotus silk: the fabric of the future

Imagine if the next global fashion sensation did not emerge from Paris or Milan but quietly bloomed in a lotus pond in the wetlands of Bangladesh.

It may sound unlikely, but Bangladesh has achieved something extraordinary -- it has produced a new kind of textile called lotus silk. Soft, glossy, and eco-friendly, the fabric is made from the stems of pink lotus flowers that grow in water.

In an era of climate urgency and demand for sustainable alternatives, Bangladesh's innovation -- a rare, biodegradable, and luxurious textile crafted from the pink lotus (Nelumbo nucifera) -- could mark a turning point.

To showcase its potential, a special six-yard-long scarf has already been produced from this lotus yarn. The scarf is currently kept at the office of the Bangladesh National Commission for Unesco in the capital, standing as a symbol of what Bangladesh's wetlands and homegrown ingenuity can offer the world.

Researchers and experts said for the first time, this special fabric is being made in the country and it could help Bangladesh emerge as a leader in smart and green fashion.

The breakthrough came through a research project titled "Study of Diversity and Conservation of Lotus from Bangladesh," initiated in 2021 by Bengal Plants Research and Development (BPRD), with funding from the Bangladesh National Commission for Unesco.

"This is not just a scientific innovation; it is a cultural renaissance in Bangladesh," said Sikdar Abul Kashem Shamsuddin, chairman of BPRD and lead researcher of the project. "For generations, the lotus has been part of our heritage. Now it is also a part of our sustainable future."

Rakha Hari Sarker, a supernumerary professor at the Department of Botany at Dhaka University, is the consultant for the project titled "Diversity, Uses, and Conservation of Lotus."

He said the lotus petiole has an incredible natural fine filament that can be transformed into high-value fibre with minimal intervention. "It's organic, it's durable and, above all, it's ours," he said.

Researchers said the lotus flower has always been seen as a symbol of purity, but now it is offering something more -- a clean, green solution to one of the world's one of the most polluting industries: textiles.

Lotus fibre cloth may seem like a new idea to many, but people in countries like Thailand, Cambodia, Myanmar, and Vietnam have long made this soft and strong cloth. Buddhist monks in Cambodia and Myanmar wore lotus fibre clothes as a symbol of peace and purity.

The first lotus cloth was reportedly made in Myanmar by Daw Sa Oo. She picked a lotus flower from Inle Lake and noticed threads coming out of its stem, which gave her the idea to weave them into cloth. She later gifted the first lotus robe to a monk.

Now, lotus fabric has become a growing business that helps rural women earn money while protecting nature.

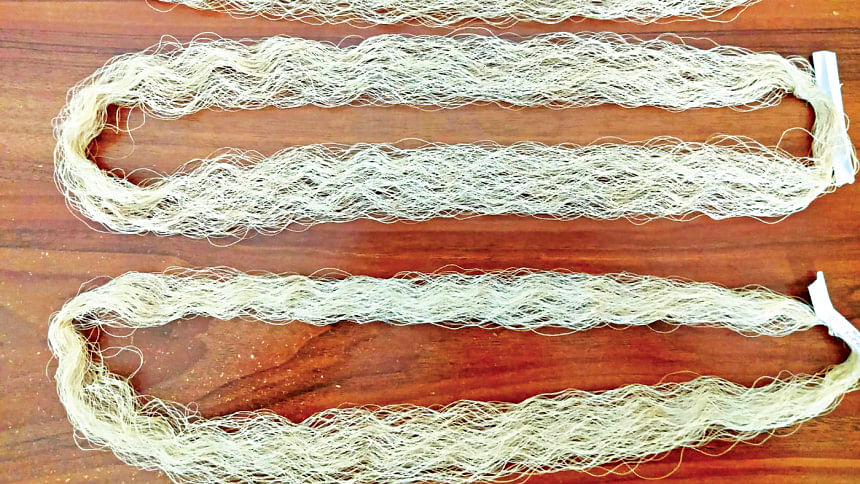

The transformation from flower to fabric is a careful and eco-friendly process. Lotus petioles (stems) are harvested from wetlands across Bangladesh without uprooting the plant, allowing it to regenerate quickly. Inside the stem are natural sticky threads that, when exposed to air, turn into fine filaments. These are gently hand-rolled, dried, and spun into thread using traditional spinning wheels, often made from bicycle parts.

No chemicals, no fossil fuels, and no pollutants are involved in the process. Even the leftover plant matter is reused as compost or cattle feed. Each metre of lotus silk requires thread from 40,000 stems. A full garment may need up to 120,000 stems. Extracting enough lotus silk for one scarf can take up to two months, and the final product can cost ten times as much as regular silk.

In the village of Ronkail in Faridpur, rural women are now being trained to extract lotus threads, providing income and dignity. "Women who never thought they would be part of a global luxury industry are now expert artisans," said Shamsuddin.

The process of making lotus silk requires meticulous handwork and craftsmanship rooted in Bangladesh's rich textile heritage. As demand grows, it could create sustainable jobs in wetland areas while preserving biodiversity by protecting lotus-filled wetlands from farming or industrial use.

Uttam Rajbangshi, a supervisor from Ronkail village, said that from July to December, lotus grows in wetlands, and during this time, 16 people, mostly women, make yarn from the stems while four others collect the lotus. The yarn is then sent to the Bangladesh Handloom Board, where it is processed to make cloth and other useful products.

Bangladesh's wetlands, like beels, haors, and rivers, are rich in plant and animal life, but they are under threat due to rapid urban growth. "Bangladesh's beels, haors, and rivers are not just water bodies -- they're biodiversity hubs," said Prof Sarker. "Lotus cultivation can actually help preserve these ecosystems while creating jobs."

The process of turning lotus stems into cloth is eco-friendly. It uses no water, fuel, or harmful chemicals, making it a zero-emission and chemical-free method, said researchers. Even the extra plant parts do not go to waste -- they can be used as natural fertiliser or food for cows, making it part of a circular economy where nothing is wasted.

"Each time we harvest, the plant regenerates stronger," said Prof Sarker. "This is a model of how industry and ecology can work in harmony."

Lotus silk is quickly becoming one of the most sought-after eco-friendly fabrics in the world. Fashion houses in Italy, like Loro Piana, have already introduced jackets made from lotus silk that cost over $5,000. In India, a company called Hero Fashion has created a special white shirt made from lotus fibre, which resists stains and is kind to nature.

In Cambodia, Samatoa Lotus Textiles, a women-led business that won a Unesco award, has turned lotus fibre into a top choice in global fashion. These examples show that Bangladesh could also become a leader in lotus silk if the right steps are taken.

Prof Rakha Hari Sarker said, "We have the land, the workers, and now the knowledge. If we invest in better research, training, and natural dyeing techniques, we can take lotus silk to the world."

The price of lotus silk is high, ranging from $2,500 to $4,000 per kilogramme. But with many wetlands full of lotus and skilled hands ready to work, Bangladesh has what it takes to enter the global market. Still, more needs to be done. Bangladesh must build strong systems for research, green production methods, and international promotion to attract fashion brands looking for sustainable materials, said experts.

Researchers said lotus silk is made from a special natural material called cellulose found inside the stems, and the amount depends on the depth of the water. Prof Sarker said research can be carried out to improve the quality and quantity of cellulose in lotus petioles. Techniques of modern plant breeding, such as tissue culture and plant biotechnology, can be applied to increase fibre production.

The entire process used in muslin production has also been applied to lotus fibre. Officials from the Bangladesh Handloom Board and Bangladesh Garment Manufacturers and Exporters Association (BGMEA) have underscored its high potential.

Ayub Ali, chief of planning and implementation at the Bangladesh Handloom Board, said, "The yarn obtained from lotus plants is extremely fine and strong -- arguably even better than silk. One of the biggest advantages is that you can extract thread from a lotus plant up to four times a month without harming it."

"You don't even need the flowers; the yarn can be extracted just from the petioles," he added. "This is a completely natural fibre and there is tremendous potential for it in Bangladesh."

Mahmud Hasan Khan, president of the BGMEA, said, "Bangladesh has an abundance of canals and wetlands, so this can be done without major investment. At present, all materials are imported from abroad. If we can source the raw materials locally, that would be fantastic."

He said Bangladesh holds strong potential to advance even further in the global ready-made garment sector.

For all latest news, follow The Daily Star's Google News channel.

For all latest news, follow The Daily Star's Google News channel.

Comments