Sweet Success

On a warm March morning in front of a state-of-the-art facility in Gazipur, employees were found to be lining up at a large gate, designated as the entry point.

They proceeded through a "hygiene section", equipped with materials that reduce biological food hazards. Once there, they changed their shoes, washed hands, and donned aprons before entering the facility.

This unconventional scene was witnessed at a factory that belongs to Premium Sweets, one of the most popular sweet chains in Bangladesh.

This correspondent recently visited the factory, which houses 300 workers across six floors, with separate production and research units to ensure product quality. The factory also boasts insect-killing technologies.

Another extraordinary quality-control measure sees workers use a machine that removes harmful elements from raw materials such as flours and ensure nothing unsavoury is mixed with the finished products.

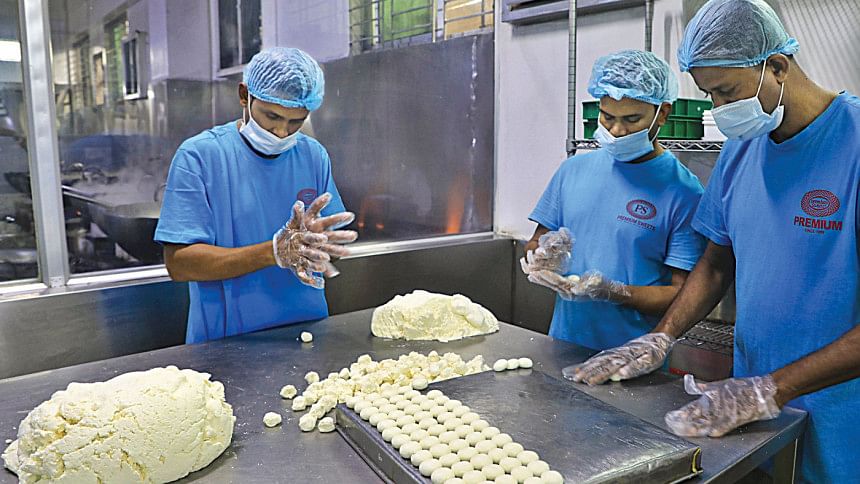

Inside, it remains constantly busy. One group of workers was seen preparing sweets while another group was working in the kitchen. Others were tasked with packaging and freezing the products that would be exported.

However, if you visit a local sweet shop in your neighbourhood and get a chance to peek behind the curtain, you may see vastly different procedures. In some shops, hygiene standards are lax at best. At others, they are altogether ignored.

The scenario, though, is changing in most shops as competition is heating up. Many corporate entities have opened outlets offering high-quality sweets. Several are also exporting items to the countries where a lot of Bangladeshis live.

Established businesses have automated the manufacturing process. For example, the production of Rosh Malai has been overhauled by the seamless integration of technologies. In the past, the balls for the delicacy were shaped labouriously using hands. Now each is precisely cut to the same size instantly thanks to the use of a sweet ball making machine.

They also uphold standards in other ways. "We don't use used cooking oil," said Mahbubur Rahman Bokul, head of Bangladesh operations of Premium Sweets.

Premium Sweets produces more than 100 types of sweets and over 15 baked items. Prices for sweets range from Tk 650 to Tk 1,200 per kilogramme while special items can fetch as high as Tk 3,500.

"People prefer branded sweets as they offer more varieties and better flavours," said HM Iqbal, founder and chief executive officer of Premium Sweets. "Hygiene also plays a big role."

The brand has 13 outlets in Bangladesh, five in Canada, and one in the US.

"We distribute sweets in every province of Canada. We plan to expand our reach to five continents by 2030," Iqbal said.

Like Premium Sweets, there are many sweets brands in Bangladesh such as Mithai, Rosh Sweets, Well Food, Banaphul Sweets, and Bikrampur Mistanno Vandar.

In 2015, Pran Group opened around 40 shops under the Mithai brand in Dhaka. Kamruzzaman Kamal, director for marketing at the conglomerate, says that the growth in the business has been good so far and they ensure the best quality and hygiene.

"Everyone makes sweets with milk. However, when it comes to milk, customers want to know how it is sourced. So, when sweets are made by a corporate organisation, consumers feel more confident."

In 2001, Well Food and Beverage Company Limited, a concern of the Well Group of Industries, started its journey with the flagship outlet at GEC Circle in Chattogram.

Well Group was founded in 1973 but only gained popularity through its food items. About 3,000 people are employed at Well Food now.

"We made the foray into the food segment as a hobby when we started a bakery business. Finally, we entered the sweets business," said Syed Nurul Islam, CEO of the Group.

"In Bangladesh, there is a good corporate market for the sweet business. So, why not start one?"

Well Food has 110 outlets in Chattogram, Dhaka and Sylhet divisions.

Another popular brand is Meena Sweets, a subsidiary of Gemcon Group, which has 22 outlets in the capital city.

"Most of the sweets in the market are produced using powdered milk that tastes different. But we source milk from dairy farms," said Ahmed Shoyeb Iqbal, chief operating officer of Meena Sweets.

Bengal Group has launched a sweet brand but with a unique twist.

Named "Banglar Misti", its outlets showcase and sell all the popular sweets from at least 35 districts. For instance, consumers can buy Mymensingh's Monda, Netrokona's Baalish Mishti, Chapainawabganj's Posto-kodom, and Rajshahi's Raghobshai at the outlets.

More mature lovers of sweets in Dhaka may be familiar with some of the oldest and most popular brands like Moronchand, Alauddin Sweetmeat, Ali Baba Sweets, Bismillah Sweets, Muslim Sweetmeat, and Al-Islamia Sweets. But it has been far from smooth sailing for them in recent years.

A large number are running their shops solely based on their brand name and with little regard to quality or taste, costing goodwill, while others have seen ownership fragmented as generations progress.

Alauddin Sweetmeat started in 1983 and opened several outlets across Bangladesh. Soon, its proprietor Hazi Masum turned the inherited business into a limited company. It later set up multiple branches abroad.

The company's successful run did not last. Currently, Hazi Masum's son-in-law Md Maruf Ahmed runs the business under the name of Alauddin Agro-food Products Company.

Among a handful of traditional sweet stores that have managed to avoid such troubles and blossom is Banoful & Co. Currently, it has 170 outlets in Bangladesh, including 89 in Dhaka. It also has stores in London and Dubai.

The exact number of sweet shops in Bangladesh is hard to come by. Dedarul Islam, director of Banoful, and also the president of the Bangladesh Sweet Manufacturers Association, says they plan to carry out a survey soon to find out the exact figures.

Market players estimate the market size to be around Tk 20,000 crore.

For all latest news, follow The Daily Star's Google News channel.

For all latest news, follow The Daily Star's Google News channel.

Comments