Dhaleshwari faces risk of salinity

A huge quantity of dissolved salt will be discharged into the Dhaleshwari river from the Savar Tannery Industrial Estate as the central effluent treatment plant (CETP) there doesn't have the component needed for desalinising wastewater.

Even if all the other toxic materials are treated, the salt will kill the biodiversity of the river, say environmentalists. The country's tannery industry uses around 40,000 tonnes of salt annually.

Now it won't be possible to add the desalinisation unit to the CETP, officials say as the setting up of the long-awaited plant at the industrial estate is almost complete.

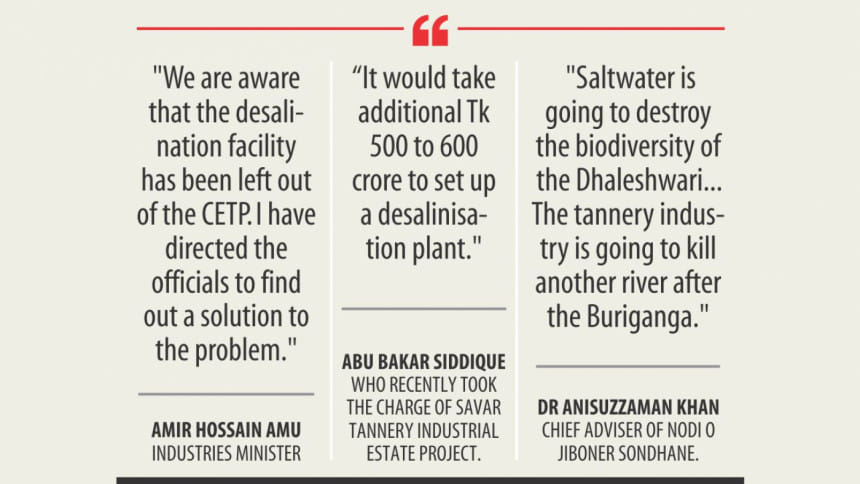

"Yes, we are aware that the desalinisation facility has been left out of the CETP. I have directed the officials to find out a solution to the problem," said Industries Minister Amir Hossain Amu, who had taken it as a mission to relocate the tannery industries from Hazaribagh to Savar.

Abu Bakar Siddique, who recently took the charge of Savar Tannery Industrial Estate project, said they were yet to devise a plan to install any central desalinisation machine as it will require a huge amount of money.

No plan for desalinisation of wastewater was included in the CETP project during the approval process “may be to reduce the cost”, he said.

There are two methods to remove salt from water -- “vaporisation method” and “reverse osmosis method”, he mentioned.

"Both the methods are very expensive. It would take an additional Tk 500 to 600 crore to set up a desalinisation plant," said Abu Bakar Siddique, an engineer.

Currently, their plan is to request the tanners to use less salt for preserving rawhide.

"We are also planning to ask all tanners to install de-dusting machines that would extract salt from rawhide before tanning process," he told The Daily Star. "This way, we can reduce around 50 percent salt in the wastewater."

Salt is the main ingredient for cattle rawhide preservation. Rawhide contains water and it is dehydrated using salt before the tanning process begins.

The tanners collect half of their rawhide during the Eid-ul-Azha. They use around five to six kgs of salt to preserve rawhide of one cow.

"The annual demand of salt in the tannery sector is around 40,000 tonnes, 20,000 during the Eid-ul-Azha alone," said Shahin Ahmed, president of Bangladesh Tanners Association.

The owners of big factories would be able to set up de-dusting machines. But out of 154 tannery units at Savar, 77 together have been allotted only 10,000 square-feet of space.

“The owners of those small units would not be able to set up de-dusting machines. The government should think about it," said Shahin Ahmed.

Tanners use salt also during the tanning process of leather. It won't be possible to remove this salt, which directly gets mixed with the waste water, he added.

As of last year, the tannery factories in Hazaribagh daily produced about 21,600 cubic metres of environmentally hazardous liquid containing chemicals such as chromium, sulphur, ammonium, salt and other chemicals.

The Savar project took off in 2003. The plan was to complete it in 2005 at an approximate cost of Tk 175.75 crore. As it was rescheduled thrice, the cost went up to Tk 827.99 crore.

In a recent visit to the tannery estate, it was seen that the authorities have been running the plant on a trial basis, treating the liquid waste from the 47 units now operating in Savar. Another 107 units are supposed to be relocated to Savar from Hazaribagh.

Waste, generated in the test run that began after the Eid-ul-Azha in October last, is discharged into the river.

The Department of Environment recently tested the water of river and found the waste was not treated properly. Conducted on January 5, the test found more than 80 microgram of salt along with other pollutants in one litre of the river water.

"Saltwater is going to destroy the biodiversity of the Dhaleshwari. It is not a wise investment if the CETP does not treat the salt. The tannery industry is going to kill another river after the Buriganga," said Dr Anisuzzaman Khan, chief adviser of Nodi O Jiboner Sondhane, a river biodiversity-related project of the Prime Minister's Office.

Already locals are complaining that fish species have been in decline since the tanneries started moving to Savar from Hazaribagh.

They saw dead fishes floating, allegedly a consequence of dumping of liquid waste directly into the water body through a channel over the last three months ago.

However, engineer Abu Bakar Siddique said already the biodiversity of the river was destroyed as many industries had been discharging waste water into it.

"The quality of our treated water is better than the river water. Because the river water is already polluted," he said.

For all latest news, follow The Daily Star's Google News channel.

For all latest news, follow The Daily Star's Google News channel.

Comments