Made in Bangladesh, played in Bangladesh

Musicians in the country, more often the young and emerging ones, have always faced the dilemma of choosing between a quality instrument and an affordable price. The more established artistes of the scene have, at some point, had to look beyond the border for instruments that suit their styles well and translate their muses into the type of music they want to create.

When it comes to the musical instruments that are "Made in Bangladesh", the motivation lies mostly within these reasons.

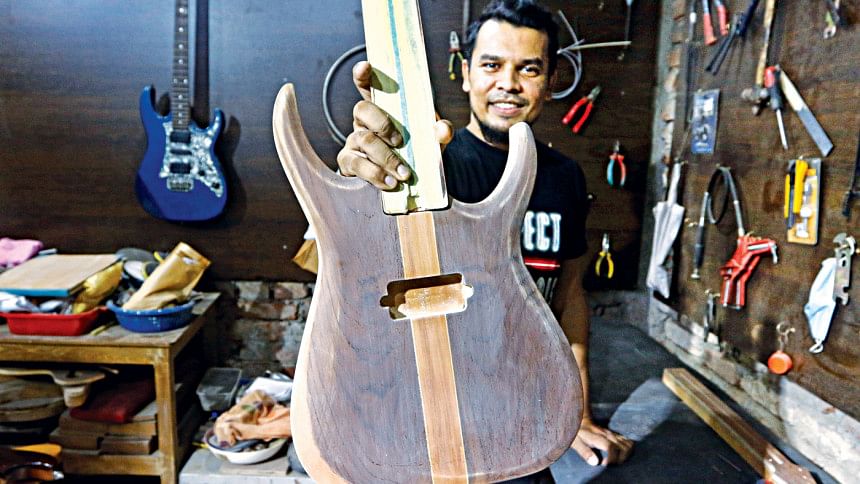

Take Beshi Joss Customs for instance. Nafeez Al Amin, one of the most dynamic drummers in the music scene, became a fully-fledged craftsman with Beshi Joss Customs a few years ago. What originally started as a passion project for the Arbovirus drummer, is now a workshop of dreams for all sorts of musical instruments, especially custom-made guitars.

The idea came to him when he was dissatisfied with the purchases he made in the country. Bringing instruments from abroad would entail a significantly higher cost as well. That is when he decided to make his own instruments.

"I started learning woodcrafting and snare-making solely from online sources, namely YouTube videos," says Nafeez. "Eventually, I founded Beshi Joss, a name borrowed from colloquial Dhaka street lingo, in 2015." At the time, it was a small drums workshop on the rooftop of Nafeez's family home in Baridhara DOHS, before eventually moving to a larger workshop in Ashulia.

Eventually, the production moved towards guitars and cajons as well, and the current workshop in Mirpur 12 displays all these instruments from Beshi Joss Customs.

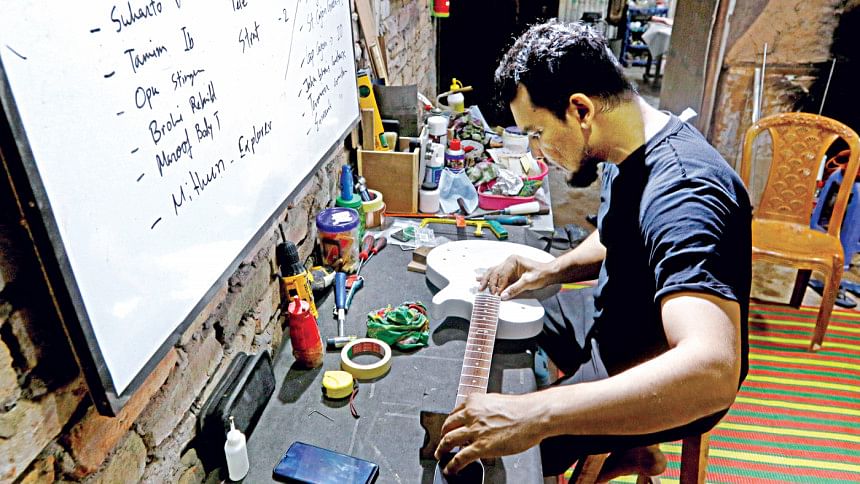

Osiris Guitars is a comparatively newer venture that caught the eyes of the people in the music scene in 2020. However, the idea was conceived around the same time as Beshi Joss, when Mahbub Alam, founder of Osiris, started working on instruments inside his room during a particularly hard time of his life. According to Mahbub, music was the only thing that could sustain him at that point.

"I was young, and didn't have enough money to buy myself an electric guitar. So, I decided to make my own. After a few years, I realised this was something that I could do professionally, and young musicians from the scene would benefit from the venture as well," says Mahbub, popularly known as Sam, while talking about his motivation behind starting Osiris.

Sam opened a Facebook page and named it BluesDen. Initially, it was merely about maintenance services.

In 2016, Sam introduced BDCajon, the first trial production product, which went on to become an established cajon brand in the country. In 2018, Rupali Guitar, their first production model acoustic, was launched. Osiris officially started its journey in 2019, and was publicised in 2020, after a year-long gap due to the pandemic.

"It's a journey that was made possible with sheer will and motivation. It was not well-planned, but the love for music and instruments led the way," says Sam, looking back on his journey with Osiris.

The goal was to make quality musical instruments affordable for aspiring musicians. Osiris currently has guitars for both beginners and collectors. Their RODEO series for beginners ranges from BDT 18,000, while similar instruments manufactured in China are available in the market at BDT 28,000.

According to Nafeez, the strength of the locally produced instruments is that they are customised and personal to whoever owns them, blending perfectly with the distinct style of each musician.

"This phenomenon generates more motivation among our musicians, especially the young ones. There is a certain sense of pride and belonging as well, when you play something that is made in Bangladesh, particularly for you," he says.

Sam's opinion in this regard echoes that of Nafeez. "Musicians love to explore. They are on the constant cusp of trying to find a new sound, a new muse, to create their next piece. If there are quality instruments available locally, it only makes this creative process easier. And that helps the music scene to grow," he says.

In terms of the price-performance ratio, these ventures have pledged to offer the best deal to the musicians. "When it comes to the price-performance ratio, I think we deliver more in value compared to the price we charge. The market has an abundance of Chinese products of subpar quality, and most companies that import instruments don't provide after-sales services like us," says Nafeez.

This claim has been vouched for by established artistes of the country's music industry as well. Kazi Faisal Ahmed, lead guitarist of Artcell, believes that the production quality of locally manufactured instruments has improved tremendously. He is currently working in collaboration with Beshi Joss Customs, to bring out his signature series of guitars, announced in October last year.

"The series is currently under an experimental phase. The philosophy behind the series was to introduce more affordable guitars for the young learners, who can spare BDT 20,000 to 25,000 for one guitar," says Faisal.

"We wanted to ensure the best quality in the production, and so we had to import new electronic materials from Korea to replace the Chinese materials we had used before, as the Chinese ones didn't yield the quality we were looking for. This raised the price margin slightly," he adds.

On the other hand, Raef Al Hasan Rafa, one of the most versatile musicians in the country, thinks the local manufacturing industry needs more work to reach perfection.

"As a professional musician, I'm willing to play them on stage, and I have. However, I will not go to record with these instruments," says Rafa.

"It's great that we have started manufacturing instruments, It's about time. If we can make clothes that international brands are buying, we can be there with instruments as well. There are more pros than cons with the customisation and after-sales servicing facilities, and the local production is one hundred times better than even the neighbouring Indian production," he adds.

However, the AvoidRafa frontman emphasises that these units have a long way to go. "We need more time, maybe a couple of years, to perfect these locally manufactured instruments," he adds. "We need a proper survey and more research on this front. This has already helped the music scene immensely, and once we're there, there's no stopping us."

Faisal believes that with a focus on quality, local brands might even get international recognition in near future.

"Esteemed musicians all around the world have played handmade instruments, so it has a good prospect in the exporting arena if we can maintain the quality," says Faisal. "However, mass production will require interest from investors as well."

These hopes have already started to materialise with these two ventures. Beshi Joss Customs has entered the exporting arena. In 2021, they produced 25 pieces of instruments and delivered them abroad, and hope to expand further on this front.

Sam of Osiris also shares their plans of going international. "For now, we are working on our production models which will be available in local music stores all over the country in 2022. We also hope to take part in the National Association of Music Merchants (NAMM) show this year and introduce 'Proudly Made in Bangladesh' Osiris Guitars to the global market," he says.

Sam holds a firm belief that the instrument manufacturing industry is bound to flourish.

"I'm assuming we will be proper instrument manufacturers in five years. There is a huge lack of technical knowledge and human resources in the sector, which we need to address. But time changes. With our strong cultural background, along with the right climate and the best of raw materials, what could possibly stop us?"

Nafeez wants to focus on keeping the motivation intact, and strengthening the technology to help the sector grow.

"I can say from my experience that there is a huge demand for locally manufactured instruments, which means that there is scope to go for mass production. If we can only stop being lazy about it and focus more on production technology and innovation – like Indonesia and the Philippines – the way ahead will only be onwards and upwards," he hopes.

The author is Sub-editor, City Desk, The Daily Star. Email: [email protected]

For all latest news, follow The Daily Star's Google News channel.

For all latest news, follow The Daily Star's Google News channel.

Comments