For RMG, digitisation is the way to go

New developments in technology, robotics, automation and digitisation are something all garment manufacturers need to be mindful of. Knowledge, as they say, is power.

There are two ways of looking at this. The first is from the perspective of how we can use technology to drive productivity and other improvements—sustainability being an obvious example in our own factories. The second aspect is the extent to which "Industry 4.0" represents a threat to Bangladeshi garment manufacturers and how much we should view it as a new form of competition.

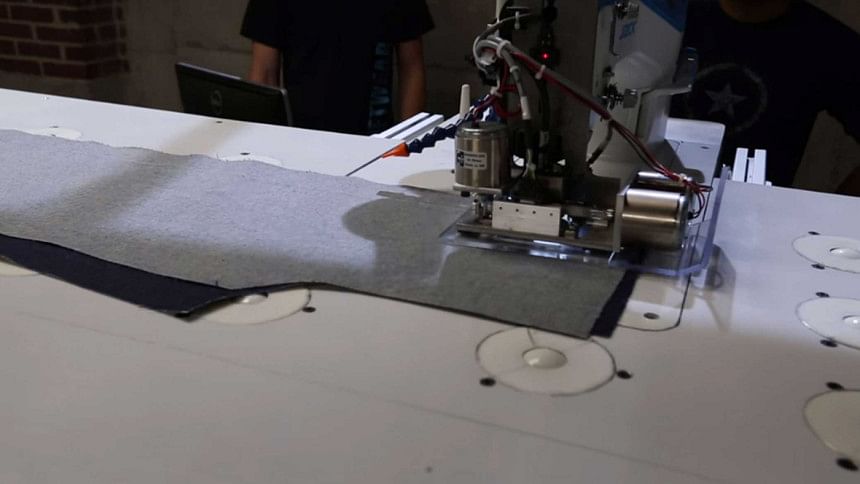

This week, I read about a garment manufacturing social enterprise called Fashion-Enter Ltd (FEL). FEL has recently entered into a collaboration with a well-known digital printing company, Kornit Digital, to open what is being described by some as the world's most sustainable and efficient end-to-end garment micro-factory.

The factory, based in London, United Kingdom, uses direct-to-fabric and direct-to-garment digital printing machines and according to press reports, these can take a dress "from pixel to parcel," or from a design on-screen to being ready to be shipped, in as little as 25 minutes. All of these processes take place at the same site in one seamless, efficient, sustainable operation, although it must be stressed that we are only talking about product samples at the present time.

It is also claimed that Kornit Digital's process removes the requirement for harmful textile chemicals (a huge concern for global fashion retailers) and uses a minimum amount of water.

Not surprisingly, there is already talk of this "factory of the future" being replicated across the UK. Every fast fashion retailer in the world is now looking at ways to decrease the time it takes to get the latest fashion styles into the wardrobes of consumers. That said, most wise observers believe this kind of sophisticated, fully digitised production will remain in the domain of mid-to-high end apparel for the foreseeable future.

Should we, as garment makers, be concerned about such developments? And how can we capitalise on the opportunities these amazing new technologies can offer our industry?

Of course, we cannot simply ignore the concept of "near-shoring," especially given our heavy dependence on garment exports. And we cannot turn a blind eye to or shrug off new developments in digitisation like this. After all, we are seeing a rapid shift to online purchasing of clothing and the e-commerce business model would dovetail well with a move towards digitisation in supply chains. Industry 4.0 is coming whether we like it or not.

Simultaneously, it is worth considering that talk around near-shoring has been around for a great many years. The costs involved in producing clothing along fully digital and automated lines are also unclear.

Ultimately, if the garment factory of the future could be scaled effectively in a major western country, it is hard to believe somebody would not have capitalised on this opportunity before now. Perhaps I am being cynical, but experience tells me ours is a conservative industry in many ways, and change comes slowly.

All that said, as garment makers, we must be abreast of these issues and give consideration to how we can incorporate aspects of Industry 4.0 into our own operations. If the sustainability gains on offer are as great as being claimed, our customers will soon be knocking on our doors asking how we, as suppliers, can take advantage of these emerging technologies.

To this end, surely it could do no harm for some of our more progressive garment factories to think about introducing pilot lines which incorporate full digitisation. If nothing else, such lines, perhaps launched in collaboration with a major fashion retailer, would offer garment makers a chance to show what is possible and would certainly be a worthwhile exercise from a public relations perspective.

A key benefit of digitisation is speed to market and responsiveness. Our geographic location negates these potential advantages. Therefore, Bangladeshi manufacturers should consider setting up satellite operations in target markets. We are the experts in garment manufacture, and I passionately believe that if anybody is to build the factory of the future, surely it should be us.

One other possible avenue for incorporating these digital technologies would be via the formation of a strategic partnership with a global apparel maker. This could see the offering of real-time sampling to customers abroad, even providing short trial runs to test what sells. All of this could be supported by upscaled manufacturing in Bangladesh.

Embracing these kinds of new business models and routes to the end consumer will be vital for Bangladesh to ensure our apparel industry remains ahead of the game in a rapidly evolving market.

Mostafiz Uddin is the managing director of Denim Expert Limited. He is also the founder and CEO of Bangladesh Denim Expo and Bangladesh Apparel Exchange (BAE).

For all latest news, follow The Daily Star's Google News channel.

For all latest news, follow The Daily Star's Google News channel.

Comments