Cementing Best Practices: Safety in Every Layer

Cement is one of the key ingredients in making concrete, which is the most used construction material worldwide. It gives strength to concrete through a chemical reaction called hydration that takes place when it is combined with water. This inorganic powder possesses the power to shape entire skylines and requires careful handling. When used correctly, cement lays the foundation for marvels of engineering; when mismanaged, it can lead to structural flaws and hazardous consequences.

"Maintaining safety on a construction site requires supervision by someone knowledgeable about the proper use, storage, and handling of cement and construction materials, along with a clear understanding of Building Code. Ensuring safety doesn't demand extensive expertise; a basic level of knowledge can go a long way," commented Engr. Md. Shamsul Alam, Principal Structural Engineer at The Designers and Managers (TDM).

The Basics of Construction Safety

Before diving into cement-specific guidelines, it is essential to understand the broader context of construction safety. Protective equipment is non-negotiable at a construction site. Helmets, gloves, steel-toed boots, and high-visibility vests form the first line of defense against common site accidents. For cement work specifically, add safety goggles and dust masks to protect eyes and lungs from cement particles, which can be harmful if inhaled. Regular training sessions should be held to reinforce safety protocols, address new risks, and remind workers of best practices.

A Guide to Different Types of Cement

There are mainly two types of cement which are commonly produced in our country, namely CEM I and CEM II. "Different areas or buildings require specific types of cement. Unfortunately, consumer awareness is quite low in our country. Selecting the appropriate type of cement is crucial to ensuring the durability of your construction," mentioned Mollah Mohammad Manju, Managing Director of Crown Cement.

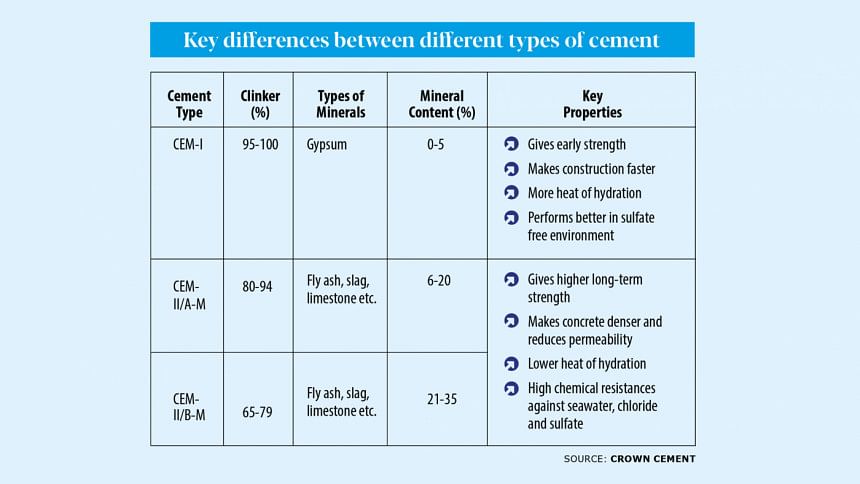

CEM I is known as Portland Cement (PC), which comprises 95% of clinker and has no SCM (Supplementary Siliceous Materials such as fly ash, slag, silica fume) added to it.

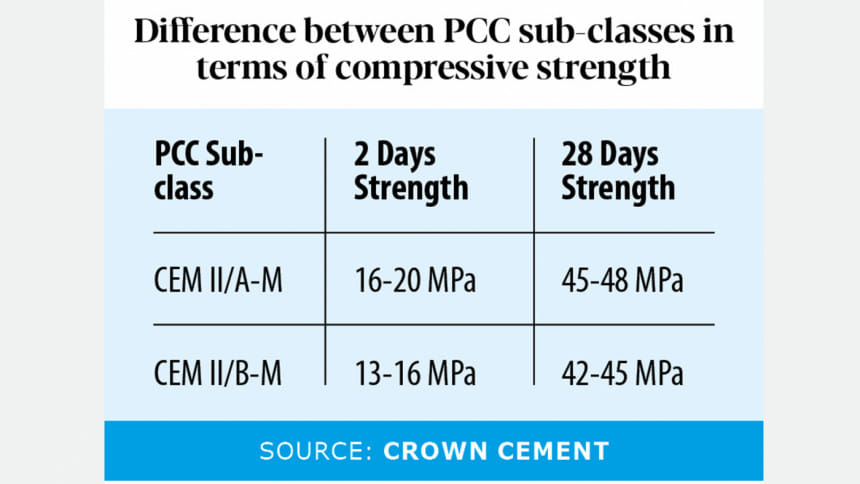

CEM II cement is known as Portland Composite Cement (PCC), where a portion of clinker is replaced by different mineral admixtures or combinations of different mineral admixtures, such as fly ash, slag, limestone, silica fume. The amount of replacement clinker varies from 20% to 35%. There are nineteen sub-class of cement in this category. Among them, the CEM II/A-M and CEM II/B-M subclasses are commonly produced in Bangladesh.

It is important to note that the quality of mineral content plays a critical role in PCC (CEM-II) cement. The quality can vary depending on the sources of the mineral admixtures. "Understanding properties of different cement is essential for proper use. Key aspects such as fineness, setting time, and strength should always be considered, and both workers and engineers must remain vigilant about these," added Principal Structural Engineer, Alam from TDM.

In short, PC offers rapid strength for quick-setting needs, while PCC ensures durability against environmental challenges like exposure to sulphates and chlorides. Additionally, structural design engineers may specify particular types of cement for specific structural elements within the design drawings.

Storing and Handling with Care

Improper storage and handling of cement can compromise cement quality and pose risks. Even a small amount of moisture can cause cement to clump and lose its binding properties. "In general, a bag of cement should be used within 60 days after production, however, if the storage condition is good, it is possible to store for 90 days or more," said an expert from Crown Cement. In case of any doubt, cement should be tested before use.

Dry and Elevated: Cement should be stored in a cool and dry area, preferably on wooden platforms to keep them off the ground. The platform should be at least 200mm (8″) above the floor and 300 mm (12″) away from the brick walls. This prevents moisture from seeping in from any side.

Stack Wisely: Maximum height of the stack shall be 15 bags and width not more than 4 bags. If stacks are more than eight bags high, the bags should be arranged alternately in length and crosswise.

FIFO Principle: Follow the FIFO (First In, First Out) method. Older cement should be used first to prevent it from exceeding its shelf life.

Lift with Care: Since cement bags are heavy, use proper lifting techniques to avoid back injuries, or employ mechanical aids where possible. Hooks should not be used during movement of cement.

Avoid Contact: Direct skin contact with cement can cause burns or rashes. Always wear gloves and long sleeves when handling it. If cement enters into the eye, immediately wash with enough water, and seek advice from a doctor. Workers must use protective hand and face coverings at the construction site.

While cement is essential, it is also a major contributor to CO₂ emissions. Incorporating sustainable practices, such as using blended cements with fly ash or slag to reduce carbon footprints, disposing excess cement responsibly, and mixing only daily requirements to minimise waste, not only benefits the planet but also improves site safety. Moreover, eco-friendly production process that reduces energy consumption and advanced technologies which cuts health hazards and pollution must be made mainstream within the industry.

For all latest news, follow The Daily Star's Google News channel.

For all latest news, follow The Daily Star's Google News channel.

Comments