Railway expansion project riddled with anomalies

The Dhaka-Tongi-Joydebpur railway expansion project was taken up without any feasibility study and approved without a fixed work scope, leading the authorities to revise the project several times, a government monitoring report said.

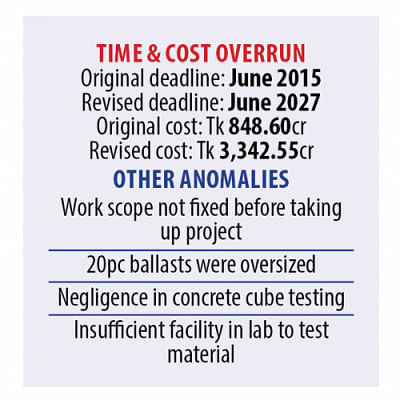

The project, which was supposed to be completed in 2015, will now take till June 2027 – a whopping 12-year delay – and will cost Tk 3,342.55 crore, almost four times the original estimate.

Besides, 20 percent of the ballast used by the project contractor were oversized, going against design specifications, while the project authorities showed negligence in the concrete cube testing, said the report.

The in-depth monitoring report of the Implementation Monitoring and Evaluation Division (IMED) has asked the authorities to retest the qualities of the ballast, rail and sleeper at the Bangladesh University of Engineering Technology (Buet).

Bangladesh Railway undertook the project in November 2012 to increase the capacity of a vital section that connects the capital with most of the country's rail network.

The Tk 848.60 crore project, aimed at constructing third and fourth dual-gauge railway lines on the Dhaka-Tongi route and a second dual-gauge line on the Tongi-Joydebpur route, was supposed to be completed within June 2015.

However, the physical work of the project began in February 2019 due to complications over design and the tender process. As per the latest revision, the project cost rose by Tk 2,493.95 crore and the deadline was set for June 2027.

Project authorities cited the Dhaka Elevated Expressway construction over the rail line in the capital, complexities over land acquisition, the Covid-19 pandemic, and the hold up in starting the physical work as the major reasons behind the delay.

WHAT THE IMED REPORT SAYS

According to the recently released IMED report, the project saw 63.75 percent progress till May this year, against the revised target of 86.36 percent by this time.

The report stressed how this project was taken up without any feasibility study, while such a study is vital for any project.

On the other hand, the project's original Development Project Proposal (DPP) was approved without identifying and specifying the work scope, the report said.

The DPP was then revised twice, with the latest revision done last month, documents show.

Asked, Project Director Nazneen Ara Keya admitted that the project indeed was taken without a feasibility study and the work scope was not fixed beforehand.

As per a provision included with the project, a detailed design was done and thus, the work scope was widened after that, she said.

The IMED report suggested conducting proper feasibility tests before taking up any project and that DPPs be prepared considering reality to avoid time and cost overrun.

POOR MATERIALS & TEST NEGLIGENCE

The report said an inspection of the site found a laboratory with insufficient facility, rendering it incapable of ensuring quality of the material.

The team observed the curing management of concrete cubes and a fixed date for testing but found that no initiative was taken for cube testing even after its maturity date had passed, it said.

The responsibility for such negligence or working against the contract falls on the consultants, engineers and contractor, the report further said, adding that the project implementing agency cannot avoid its responsibility either.

The non-performance of the concrete cube test within the stipulated time raises a question about whether the structure was constructed as per the quality mentioned in the contract, it said.

The report recommended that a third party test samples from the infrastructure and the results be scrutinised by the BR's design department.

However, the project director denied the allegations and said they were based on a "wrong perception".

She also claimed they have done the test on time and following due procedure.

The report also said that when, during a field visit, it was found that 20 percent of the ballast used were oversized, the project consultant could not properly explain why it was so.

"Proper compaction is not possible if there is abundance of oversized ballast," it said.

Less compacted ballast worsen the riding quality, which may cause the rail to bend and may even lead to train accidents, the report said, adding that it appears that the contract provision was violated in this regard.

The report further said the rail line installation work from Tongi to Joydebpur was completed but the thickness of ballast on the section was found to be 20 percent less than the estimate.

The project director said, "How did they [IMED] determine that 20 percent of the ballast were oversized? They are saying it based on an assumption. We have checked and not more than five percent of ballast were oversized – which is permitted as per the contract."

Besides, the project work has not been completed yet and they will be able to add ballast, if necessary, she said, adding that they have already asked the contractor and consultants to recheck.

The report further said meetings of the Project Steering Committee and Project Implementation Committee were not being held regularly.

REASONS FOR DELAY, COST ESCALATION

Project Director Nazneen Ara said the Dhaka Elevated Expressway being constructed over the rail line in the capital was the main reason behind the delay in implementation, adding that the physical work of the railway project from Banani to Kamalapur could not begin because of this.

The expressway authority, in a letter sent to the rail authority, said it would clear the rail line up to Mohakhali, Tejgaon Station and Malibagh by July and August this year and March of next year respectively, she said.

"So, we have to plan our work accordingly," Nazneen said, adding that the expressway authority is yet to say when they will clear the Malibagh-Kamalapur section.

About land acquisition complications, she said the problem is "almost solved". Besides, the Covid-19 pandemic and the long delay in starting the physical work are other reasons behind the time extension, she added.

Meanwhile, the increase of work, redesign of the Turag Bridge, a spike in land acquisition costs, and the strong dollar were the major reasons behind the cost escalation, the project director said.

For all latest news, follow The Daily Star's Google News channel.

For all latest news, follow The Daily Star's Google News channel.

Comments